Table 6.

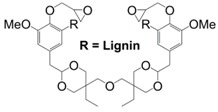

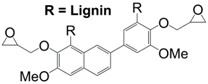

Poly-aromatic epoxy monomers from crude bio-mass and thermal properties of the cured materials.

| Epoxy | Curing Agent | Tg (°C) or Tα (°C) | Td,5% (°C) | Reference | |

|---|---|---|---|---|---|

| Materials | DGEBA Comparison | ||||

| Epoxidized depolymerized kraft lignin | Diethylenetriamine | - | - | 252 d | [186] |

| 4,4-diaminodiphenyl methane | - | - | 290 d | ||

| Epoxidized depolymerized organosolv lignin | Diethylenetriamine | - | - | 228 d | |

| 4,4-diaminodiphenyl methane | - | - | 257 d | ||

|

Phenol Novolac | 94 | 95 | - | [189] |

|

134 | - | |||

| Epoxidized lignin (Cedar) | Phenol Novolac (TD2131) | - | - | 293 | [190] |

| Lignin (Cedar) | - | - | 296 | ||

| Epoxidized lignin (Eucalyptus) | Phenol Novolac (TD2131) | - | - | 275 | |

| Lignin (Eucalyptus) | - | - | 274 | ||

| Epoxidized lignin (Bamboo) | Phenol Novolac (TD2131) | - | - | 266 | |

| Lignin (Bamboo) | - | - | 259 | ||

| Epoxidized green tea extract | Isophorone Diamine | 142 a,b | 140 a,b | 256/267 c | [193] |

| Epoxidized cardanol (NC514) | Isophorone Diamine | 50 a,b | 155 a,b | 350 | [205] |

| Jeffamine T403 | 23 | 70 | 352 e | [198] | |

| Isophorone Diamine | 41 | 121 | 350 e | ||

| 50/59 b | 158/158 b | 366 e/363 c,e | [196] | ||

| Jeffamine D400 | 15/9 b | - | 362 e/361 c,e | ||

| PE-C9-NH2 | 13 | 279 | - | [141] | |

| PE-C18-NH2 | 14 | 284 | - | ||

| Phenalkamine NX5454 | 30/38 a,b | - | 325 f/322 c,f | [206] | |

| Cardanol cysteamine | 19/21 a,b | - | 328 f/311 c,f | ||

a Tα measured by DMA at the peak position of loss modulus curve; b Tα measured by DMA at the maximum of tan δ; c Td under air flow; d IDT = initial decomposition temperature; e Td,30%; f Td,10%.