Significance

Carbon capture, utilization, and storage (CCUS) is a crucial technology needed to limit warming to the 2 °C target of the Paris Agreement. However, deployment is lagging far behind estimates of what is required. We demonstrate an opportunity to significantly expand CCUS in the United States in the near-term, spurred by new financial incentives enacted in February 2018, by targeting the lowest-cost capture opportunities and by deploying only commercially proven technologies. The carbon dioxide pipeline transport network would serve near-term oil industry demand for carbon dioxide while also connecting multiple prospective long-term dedicated geological storage resources. This would be a flexible long-term infrastructure asset for carbon management in the United States that would enable and accelerate future CCUS deployment.

Keywords: carbon capture, utilization, and storage; energy and climate policy; enhanced oil recovery; pipeline infrastructure; network economic analysis

Abstract

In February 2018, the United States enacted significant financial incentives for carbon capture, utilization, and storage (CCUS) that will make capture from the lowest-capture-cost sources economically viable. The largest existing low-capture-cost opportunity is from ethanol fermentation at biorefineries in the Midwest. An impediment to deployment of carbon capture at ethanol biorefineries is that most are not close to enhanced oil recovery (EOR) fields or other suitable geological formations in which the carbon dioxide could be stored. Therefore, we analyze the viability of a pipeline network to transport carbon dioxide from Midwest ethanol biorefineries to the Permian Basin in Texas, which has the greatest current carbon dioxide demand for EOR and large potential for expansion. We estimate capture and transport costs and perform economic analysis for networks under three pipeline financing scenarios representing different combinations of commercial and government finance. Without government finance, we find that a network earning commercial rates of return would not be viable. With 50% government financing for pipelines, 19 million tons of carbon dioxide per year could be captured and transported profitably. Thirty million tons per year could be captured with full government pipeline financing, which would double global anthropogenic carbon capture and increase the United States’ carbon dioxide EOR industry by 50%. Such a development would face challenges, including coordination between governments and industries, pressing timelines, and policy uncertainties, but is not unprecedented. This represents an opportunity to considerably increase CCUS in the near-term and develop long-term transport infrastructure facilitating future growth.

Climate change mitigation assessments consistently find that carbon capture, utilization, and storage (CCUS) is a crucial technology needed to reduce emissions of carbon dioxide to the atmosphere sufficiently to limit warming to the 2 °C target of the Paris Agreement (1, 2). These studies also conclude that the system-wide cost of decarbonizing the energy system will be lower with CCUS as part of the solution. CCUS, when combined with bioenergy or direct air capture, is also an important option among negative emissions technologies that may be needed to remove carbon dioxide from the atmosphere (3, 4). However, despite its importance, CCUS deployment is lagging far behind estimates of what is required to meet the Paris target (5). Only ∼31 million metric tons (Mt) per year of anthropogenic carbon dioxide are currently captured and injected into geological formations for permanent storage (6), while analyses estimate that 200–1,000 Mt per year will be required by 2030 and 5,000–10,000 Mt per year by 2050 (7–10). CCUS has been held back by inconsistent and insufficient policy support, a lack of economic drivers, and the inherent large scale and associated large cost of individual projects (11).

After years of relatively little policy support, in February 2018, the US Congress passed substantial tax credits that incentivize new CCUS projects (12). From 2018 to 2026, the Section 45Q tax credit value will increase linearly from $25.70 to $50 per metric ton of carbon dioxide for secure geological storage and from $15.30 to $35 per ton used in carbon dioxide-enhanced oil recovery (CO2-EOR) that results in secure geological storage (or other uses that permanently store carbon dioxide). The tax credit value will increase at the rate of inflation after 2026. CO2-EOR operations typically pay an oil-linked price near 40% of the per-barrel oil price for a ton of carbon dioxide ($23 per ton at the April 2018 oil price of ∼$60 per barrel), which adds value for the case where captured carbon dioxide is used for EOR (13, 14). Capture projects must begin construction by January 1, 2024, to receive the credits and, once in service, will receive those credits for a 12-y period.

The tax credits will likely be insufficient to incentivize widespread carbon capture retrofits on electricity generation plants, considering the current relatively high estimated capture costs around $50 and $75 per ton of carbon dioxide for coal and gas plants, respectively (15, 16). However, they will provide a strong incentive for lower-capture-cost opportunities, which are typically industrial sources with relatively concentrated carbon dioxide waste streams with capture costs in the range of $10 to $55 per ton (17–21). Given our daunting climate targets and the need to rapidly scale up CCUS, these low-capture-cost sources represent an attractive pathway for near-term deployment. Deploying CCUS on these sources will not only reduce emissions, but also give an opportunity for additional learning, cost reductions, and the construction of transport infrastructure that will help enable and accelerate future CCUS projects. With this as motivation, we investigate the following questions: Can the tax credits provide sufficient support to enable construction of large-scale (>10 Mt per year) carbon dioxide capture and transportation infrastructure? What additional policy support might be needed? What other challenges need to be addressed? To answer these questions, we consider the lowest-capture-cost carbon dioxide sources in the United States, the pipeline infrastructure needed to transport that carbon dioxide to where it can be utilized and stored, and whether the tax credits provide sufficient value to make the system economically viable.

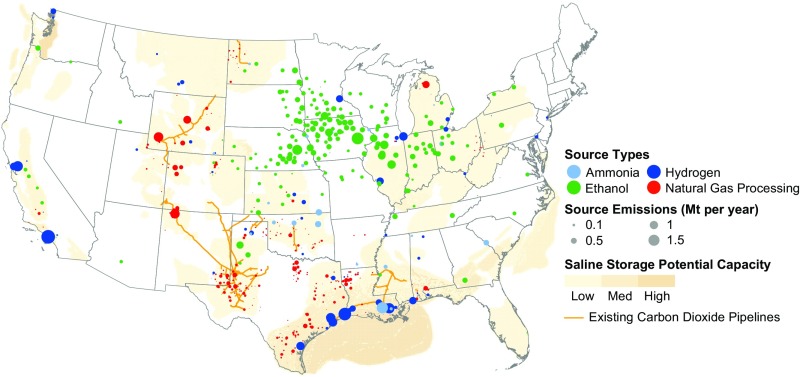

Fig. 1 shows the location and size of low-capture-cost sources in the United States. We include only source types for which there are already commercially implemented capture technologies and existing large-scale carbon capture projects and, therefore, for which carbon capture could be deployed within the next several years. The sources include natural gas processing, ethanol fermentation at biorefineries, and hydrogen and ammonia production, which account for a total of 87 Mt per year of emissions with low capture cost (more information on the emissions data and estimation is included in SI Appendix). The map also shows the location of deep saline aquifers with potential for geological carbon storage and existing carbon dioxide pipelines that serve the CO2-EOR industry.

Fig. 1.

Low-capture-cost carbon dioxide emissions in the United States, existing carbon dioxide pipelines, and potential saline storage formations. Colocated sources are summed so that the total emissions are observable. Total emissions are 87 Mt per year, including 43 Mt from ethanol fermentation at biorefineries, 22 Mt from hydrogen production, 5 Mt from ammonia production, and 17 Mt from natural gas processing. Data sources are listed in SI Appendix.

The Midwest stands out as the region with the greatest quantity of low-capture-cost emissions (40 Mt per year and almost 50% of the US total). The Midwest sources also stand out because they are not located near existing carbon dioxide pipelines, and they mostly do not overlie potential saline storage reservoirs. To capture a substantial proportion of these carbon dioxide emissions, a regional pipeline network would be needed to aggregate emissions from many sources and transport the carbon dioxide to storage locations. Carbon dioxide from ethanol fermentation constitutes most of the Midwest low-capture-cost emissions (35 Mt per year and 90% of the Midwest total). A network based on these sources may be economically attractive since ethanol fermentation is a particularly low-cost capture opportunity: Ethanol fermentation generates a gas outlet stream that is >99% carbon dioxide (once moisture is removed) and thus requires only compression and dehydration (22, 23). Correspondingly, carbon capture on ethanol biorefineries is already commercially deployed. There are ∼210 ethanol biorefineries in the United States, of which ∼40 already capture at least some carbon dioxide for sale to the EOR, food and beverage, and dry ice industries (22, 24–26). At the largest scale, Archer Daniels Midland’s (ADM) Decatur ethanol biorefinery captures nearly 1 Mt per year and injects it into a saline aquifer in a government-funded demonstration project (23, 27). Therefore, we focus our study on the feasibility of capturing emissions from the Midwest region, with a particular focus on ethanol biorefineries and on developing a pipeline network to transport the carbon dioxide. Other regions have either fewer low-capture-cost sources or existing carbon dioxide pipelines and, consequently, are not considered in our analysis.

The carbon dioxide pipelines in Fig. 1 supply carbon dioxide from natural and anthropogenic sources to oil fields for CO2-EOR (28), an activity that involves the injection of carbon dioxide into depleted oil reservoirs to induce additional production (22, 29). Carbon dioxide injected for EOR is ultimately securely stored in the oil reservoirs (14, 30). About 63 Mt per year is currently injected for CO2-EOR in the United States, of which ∼78% is sourced from natural underground reservoirs and 22% from anthropogenic sources (14, 24, 28). CO2-EOR drives most existing CCUS: Of the 31 Mt of anthropogenic carbon dioxide emissions currently captured and stored globally each year, 90% is for CO2-EOR, mainly in the United States (6). Just 1 Mt is injected for dedicated geological storage in the United States each year (the ADM project). About 4% of domestic oil production is through CO2-EOR (31). The size of the CO2-EOR industry is limited by lack of affordable carbon dioxide supply rather than a lack of potential (14, 30, 32, 33): Oil reservoirs in the United States could store enough carbon dioxide to meet projected carbon storage requirements under a two-degree pathway until at least midcentury (7, 13, 29).

We therefore specifically target our study on transporting captured carbon dioxide to regions with demand for EOR. We focus on storage through CO2-EOR rather than dedicated storage for a number of reasons:

(i) The United States has an established CO2-EOR industry with large potential for expansion (29, 34). CO2-EOR projects can likely be developed more quickly than dedicated storage projects, which face more stringent regulations and for which there is little experience (35, 36).

(ii) The pipeline infrastructure would also be a long-term asset for dedicated carbon storage, crossing several prospective saline aquifer storage formations (Figs. 1 and 2).

(iii) The use of captured carbon dioxide for EOR is likely to be the most economically favorable option. Given the location of most ethanol biorefineries, a regional pipeline network would need to be developed in either case, so transport cost would be similar for EOR or dedicated storage. Once the carbon dioxide has been transported, there would be additional cost for dedicated storage; by contrast, additional revenue is earned when the carbon dioxide is sold for CO2-EOR. This differential is likely to exceed the $15 per ton tax credit differential: Dedicated storage costs are typically about $10 per ton (15, 17), while sales revenue is typically around $20 per ton (at the April 2018 oil price), a $30 per ton differential. While delivering greater value, the CO2-EOR option also has additional risk through exposure to volatile oil prices.

(iv) Major carbon dioxide capture and pipeline infrastructure projects based on CO2-EOR are likely to be more broadly and strongly supported because they also benefit the oil and gas industry and oil-producing states. Indeed, it was a coalition including oil-state Republicans and climate-focused Democrats that enabled the passing of the increased tax credits (12).

(v) Tax revenue to federal and state governments due to additional oil production from CO2-EOR substantially covers tax revenue forgone by the tax credits. Governments receive about $10 in tax per barrel of oil produced, or $20 to $30 per ton of carbon dioxide used in EOR (37). Use of carbon dioxide for CO2-EOR may therefore give a fiscal argument for policies that support CCUS.

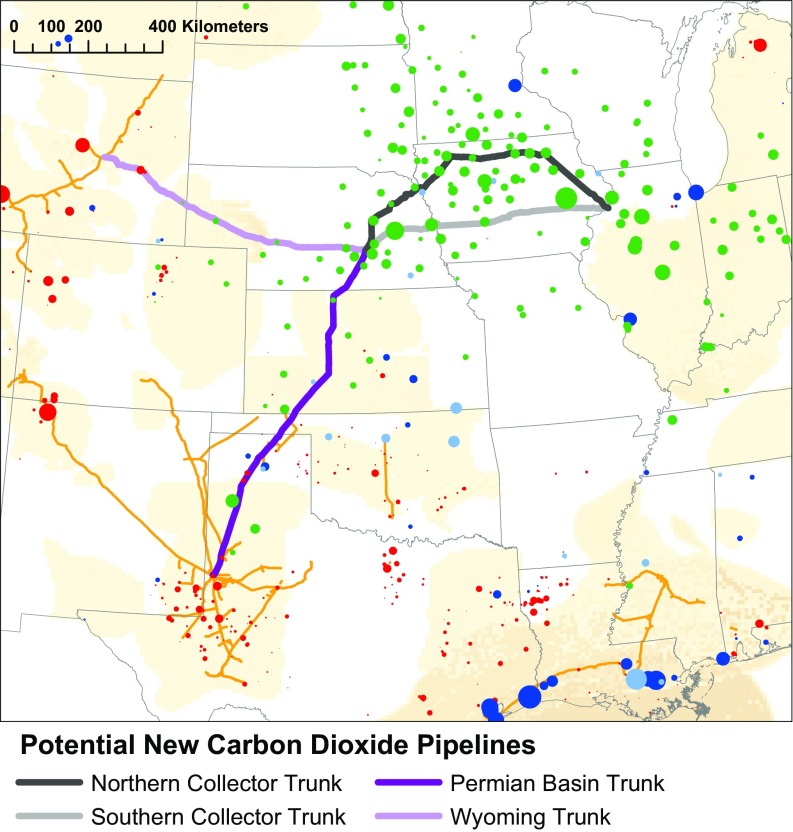

Fig. 2.

Potential carbon dioxide trunk pipelines that were analyzed, including a northern collector trunk through the center of the spatial density of low-capture-cost sources in the Midwest, a southern collector trunk linking the largest Midwest sources, and delivery trunks to Wyoming or the Permian Basin. Data sources are listed in SI Appendix.

A concern with the use of captured carbon dioxide for CO2-EOR is that associated oil production could offset the emissions benefit of storage. However, a number of studies have found that CO2-EOR does result in a significant net emissions reduction on a lifecycle basis. Injection of carbon dioxide for CO2-EOR results in its permanent storage in the oil reservoir, with minimal carbon dioxide lost in the process (14, 30). Each ton of carbon dioxide injected yields two to three barrels of oil production (with variability between different oil fields) (29, 30, 38, 39), which result in ∼1.2 tons of carbon dioxide when used (30). These are not net additional emissions, however, since each barrel of oil produced by CO2-EOR mostly displaces other oil in the market. The International Energy Agency estimates that 80% of each barrel displaces other oil production, and that, after accounting for all factors including the amount of oil produced, energy use in CO2-EOR operations, and the market impacts, each ton of carbon dioxide injected for EOR results in 0.63–0.73 tons of carbon dioxide emissions abatement on average (30). Precise calculation of the net emissions benefit of each CO2-EOR project is complex and depends on the properties of the oil reservoir, the EOR process used, and market factors, including the type of oil displaced. Still, it is clear that a significant net emissions reduction results from CO2-EOR.

Our analysis uses existing carbon dioxide capture and pipeline cost models and data to estimate costs. We evaluate the economic feasibility of the system considering the value of the tax credits and carbon dioxide sales for EOR. We consider four options for the basic pipeline network structure, shown in Fig. 2, which represent two options for collecting carbon dioxide in the Midwest and two options for delivery of that carbon dioxide. The collector trunk pipeline options include a southern trunk pipeline that follows the shortest path between the largest low-capture-cost sources or a northern collector trunk that passes through the center of the spatial density of sources in the Midwest. The delivery options include trunks delivering the carbon dioxide to Wyoming or to the Permian Basin of West Texas, the two regions with the largest demand for CO2-EOR (29). The pipeline pathways are restricted to existing major infrastructure corridors. After determining the best trunk pipeline combination, we evaluate three different financing scenarios for the pipeline network, representing different combinations of commercial and government financing. We ultimately estimate the total quantity of carbon dioxide that is economically viable to capture with the tax credits under different pipeline financing scenarios.

CCUS infrastructure deployment in the United States and elsewhere has been investigated by previous studies. Models have been created to optimize infrastructure considering economic, spatial, and temporal factors (40–44). The opportunities associated with deployment on ethanol biorefineries and CO2-EOR have been separately identified and analyzed (22, 45–48). Our study includes network economic optimization similar to previous work, but also integrates policy analysis by assessing the opportunity for near-term deployment in response to a recently legislated policy considering its specific parameters and constraints as well as the current economic and political environment. We also consider additional policy measures that would be required to enable large-scale deployment.

Results and Discussion

Trunk Route Selection.

The Permian Basin and Wyoming trunk options have very similar pipeline costs. The Permian Basin option requires a 5% higher total cost for a pipeline network to transport emissions from all low-capture-cost sources in the Midwest, due to the Permian Basin trunk being ∼1,000 km compared with the 800-km Wyoming trunk. However, the Permian Basin has substantially greater existing and potential future demand for carbon dioxide. Approximately 40 Mt is currently injected in the Permian Basin each year (63% of the US total) compared with ∼10 Mt in Wyoming (16% of the total) (24, 29, 32). The Permian Basin is estimated to have at least 2,300 Mt of potential future CO2-EOR demand compared with 600 Mt for Wyoming (13). The Permian Basin trunk also passes through Kansas and Oklahoma, which are estimated to have at least a further 1,800 Mt of potential CO2-EOR demand (13). Considering that the full potential Midwest low-capture-cost source network could supply 37 Mt per year, Wyoming has only 16 y of capacity (assuming that CO2-EOR projects could be scaled up quickly enough to absorb the new supply). We therefore selected the Permian Basin trunk as the better option, since the additional cost is small, but the potential to absorb the new carbon dioxide supply is much greater.

After selecting the Permian Basin trunk, we compared the northern and southern collector trunk options. The northern trunk option gives lower total pipeline network cost, despite having a greater trunk pipeline length, due to the strong pipeline economy of scale: Pipeline cost scales approximately linearly with pipe diameter, but flow capacity is determined by the pipe cross-sectional area and scales with diameter squared (49, 50). Pipelines with greater flow are cheaper per unit of flow, decreasing costs for all sources sharing the pipelines. The northern option therefore has lower total cost because sources are closer to the trunk on average, which minimizes the length of more expensive (per unit of flow) smaller-capacity pipelines needed to connect the sources to the cheaper (per unit of flow) large-capacity trunk pipeline. We selected the northern trunk as the better option. Quantitative comparison of the northern and southern trunks is included in SI Appendix.

Network Economic Analysis.

We investigated the economic viability of capturing and transporting carbon dioxide from all low-capture-cost sources in the Midwest region to the Permian Basin. We designed a pipeline network that efficiently connects all sources to the trunk pipeline. We calculated the cost of each segment in the pipeline network and the tariff the pipeline owners would need to charge for each ton of carbon dioxide transported, in order to achieve a target rate of return over the pipeline financial lifetime. The pipeline transport tariff that each source must pay was then calculated based on the pipeline network segments it uses. Capture facility cost for each source was calculated. Finally, we determined the carbon dioxide sales price that would be required in addition to the value of the tax credits for the capture facility owners to achieve a target rate of return over the capture project financial lifetime, considering the capture and transport costs for each source. (The sales price is for carbon dioxide delivered to the destination; the capture facility pays the transport cost.) More detailed description of the network economic analysis is included in Materials and Methods and SI Appendix.

After determining the required price for each source, we eliminated all sources whose required price was above a threshold set at the typical CO2-EOR price of $23 per ton of carbon dioxide (for the April 2018 oil price around $60 per barrel) (13). Only ethanol biorefinery sources remained due to their lower capture cost compared with the other source types. The removal of sources from the network reduces the number of remaining sources sharing the pipelines and, therefore, the pipeline flow rates. Due to the pipeline economy of scale, the lower flow rates imply that the cost per unit of flow increases and pipeline transport tariffs increase accordingly for the remaining sources. The pipeline tariffs and required carbon dioxide sales prices were therefore recalculated for the remaining sources (this process is called “iteration” hereon). Emissions abatement curves are often presented as static curves of quantity abated vs. unit cost, but for our CCUS network system, the cost of each unit of emissions abatement is dependent on all other units (sources) in the network: This is a dynamic system that cannot be represented by a static curve (51).

The performance of the system upon iteration depends on the transport and capture cost, price threshold, and financial parameters used in the calculations. Our base case, which we call the “full-commercial” scenario, assumes the pipelines and capture facilities are built and owned by companies obtaining finance on typical market terms (the parameters are listed in Materials and Methods). For this scenario, continued iteration of the network does not find a stable, viable system. The full initial network has a total of 37 Mt of carbon dioxide emissions, with 17.8 Mt below the price threshold. The quantity of emissions below the threshold is drastically reduced to 9.5 Mt after the first iteration of the network. After a second iteration, just 3.4 Mt are below the price threshold (see Fig. 8). A third iteration would reduce the total close to zero. The capture of emissions from ethanol biorefineries in the Midwest and transport to the Permian Basin is not viable under our full-commercial scenario parameters. Smaller systems that capture emissions from some of the largest ethanol biorefineries and transport carbon dioxide to nearer CO2-EOR opportunities in Kansas or Illinois may be viable under these parameters (22, 52), but the objective of this study is to explore the largest-scale capture and transport infrastructure that can be developed.

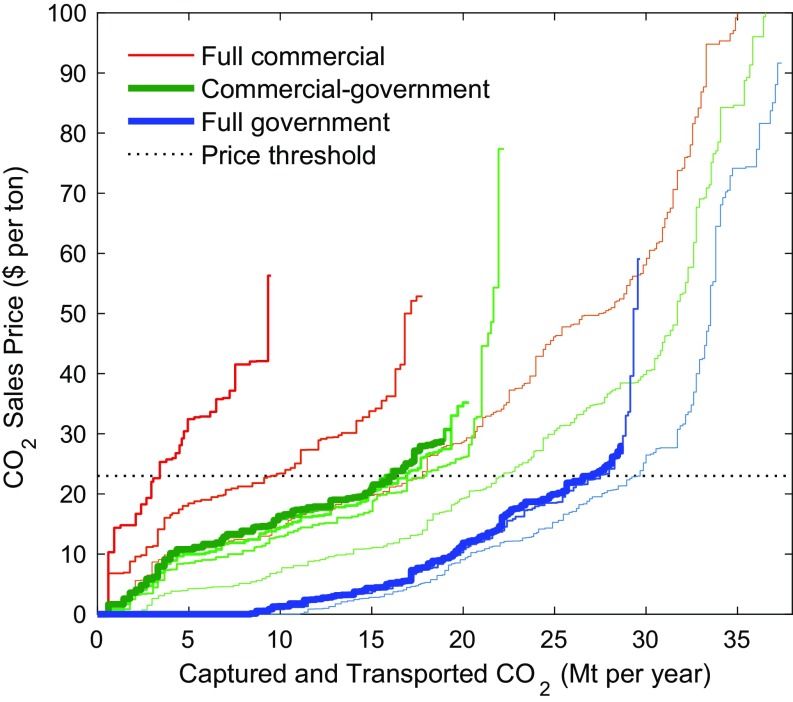

Fig. 8.

Price curve iterations for each pipeline financing scenario. The different colors represent the different financing scenarios. The thinnest line for each color is the full initial network, with subsequent iterations in darker color and with thicker lines. The thickest green and blue lines are the final, stable scenarios. The full-government scenario reached a stable network after two iterations, while the commercial-government network was stable after four iterations. The full-commercial scenario has no stable network.

We explored the sensitivity of the system to the key economic parameters to determine whether it could be viable under any conditions. The parameters included oil price (since the carbon dioxide prices paid by CO2-EOR operators are oil-linked), pipeline and capture facility capital cost, and the cost of finance for the pipelines. For the oil price and capital costs, we considered likely optimistic-case values (low capital cost and high oil price) that are shown in Table 1. We did not consider operational cost sensitivity because these costs are more directly tied to energy and labor costs that are less likely to fall.

Table 1.

Sensitivity of the initial network to optimistic-case values for the key system economic parameters

| Case and parameter value | System levelized cost reduction, % | Quantity of emissions below threshold price, Mt (%) |

| Full-commercial initial scenario | — | 17.8 |

| Low (−20%) capture capital cost | 5 | 18.7 (+5) |

| Low (−15%) pipeline capital cost | 9 | 19.7 (+11) |

| High ($80 per barrel) oil price | — | 20.8 (+17) |

| Lower (commercial-government) pipeline financing cost | 21 | 22.2 (+25) |

| Lowest (full-government) pipeline financing cost | 34 | 29.7 (+66) |

Since the commercial financing terms are set by financial markets and dependent on the inherent risk of the project, the main practical option to significantly lower the cost of finance is through government involvement, either directly (loans or grants) or indirectly (special tax structures or loan guarantees). We therefore considered two lower-cost pipeline financing scenarios with different levels of direct government financing. The first is a commercial project with half of the capital cost financed by longer-term government loans with lower interest rate than commercial debt (4.5% compared with 6%), termed the “commercial-government” scenario. The second is for the project to be fully financed by government debt (at 3.5% interest rate), termed the “full-government” scenario. There are numerous possible financing arrangements, as discussed in reports by the State CO2-EOR Deployment Work Group (49, 53), but these two scenarios represent both the opposite end of the spectrum from our initial full-commercial scenario and an intermediate option. More detailed information on the sensitivity and financing scenarios is included in Materials and Methods and SI Appendix.

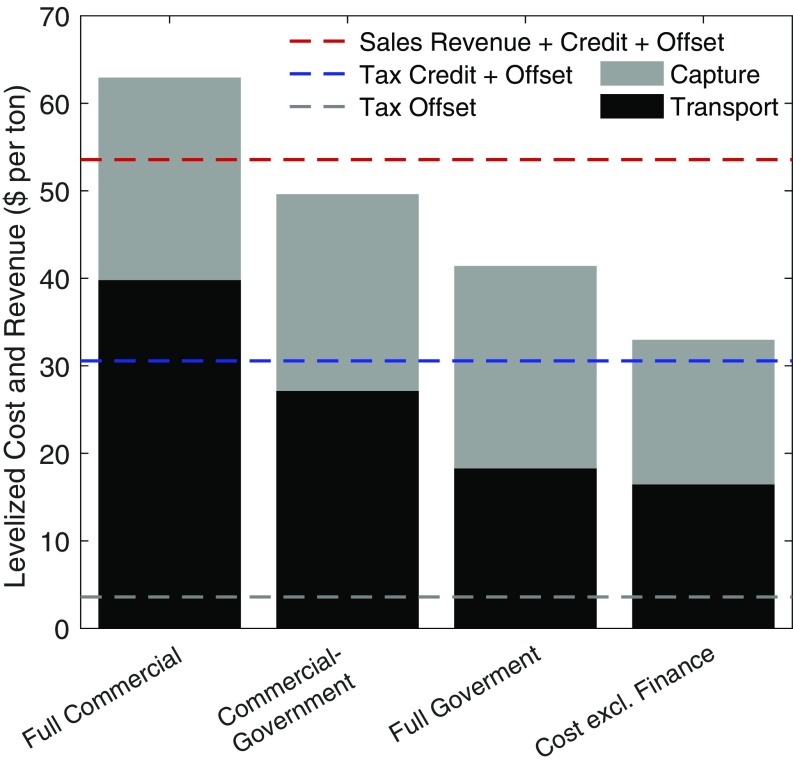

We considered the lower-cost financing scenarios for pipelines but not capture facilities for several reasons. First, greater system cost reductions are possible through cheaper finance for pipelines (see Fig. 5). Pipelines are more capital-intensive than capture facilities for ethanol biorefineries, with ∼80% of the total cost being capital and 20% operational costs for pipelines, compared with ∼50% capital and 50% operational costs for the capture facilities. The capital cost of the pipeline network is also more than double the summed capital cost of all ethanol biorefinery capture facilities in the network. Second, the capture facilities will receive financial support through the tax credits, so additional direct support may be less likely. Third, there is a stronger precedent for government financing of shared infrastructure like pipeline networks.

Fig. 5.

Average levelized costs and revenues per ton of carbon dioxide captured and transported for each network financing scenario, in 2018 dollars. Costs are shown by the bars and are the system-wide average. The revenue values are shown by dashed lines and are stacked in the graph: The tax offset value is $3.69, the tax credit value is $26.97, and the carbon dioxide sales revenue is $23. The tax credit and offset are effective revenues since they are reduced tax liability rather than cash revenue. The tax offset is the value owners gain by using capture facility net operating losses and asset depreciation to offset other taxable income. We assume that the value of the tax credits and offsets can be fully monetized by project owners. Further detail is included in SI Appendix.

Table 1 shows that the system is relatively insensitive to capital costs within the likely optimistic-case value range. The system is more sensitive to the potential oil price up-side, but this is an uncontrollable and unpredictable factor that cannot be relied upon as a pathway to system viability. The system is most sensitive to the cost of finance for the pipeline network. Lower-cost finance can substantially improve the economic viability of the system. Lower-cost financing is also a scenario that can be enabled by policy decisions, unlike the system capital (and operational) costs and the oil price. Given its impact and possibility, low-cost pipeline financing is an attractive pathway to improve the viability of the system. We therefore chose to focus on analyzing the system under the lower-cost financing scenarios hereon.

Pipeline Financing Scenario Analysis.

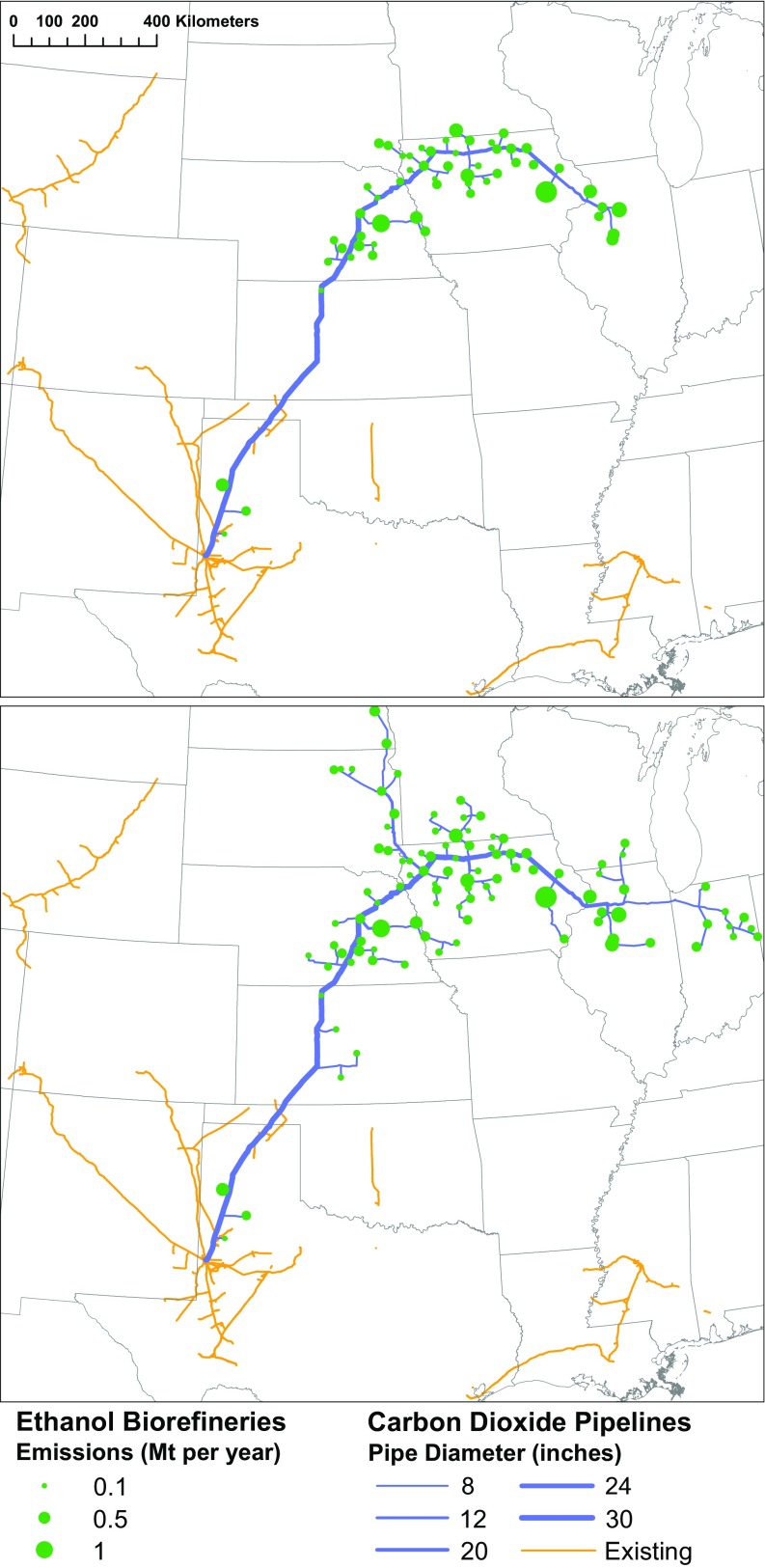

We performed the full network economic analysis and iteration process for the commercial- and full-government pipeline financing scenarios. The network analyses for both scenarios yielded stable systems with all connected capture facilities economically viable. The stable networks are shown in Fig. 3. The full-government pipeline scenario network captures and transports a total of 28.7 Mt of carbon dioxide per year from 108 ethanol biorefinery sources, compared with 19.0 Mt from 63 ethanol sources for the commercial-government scenario. The capital cost of the system is estimated to be $6.7 billion for the pipeline network and $2.6 billion for the capture facilities in the stable full-government scenario, compared with $4.3 billion for the pipelines and $1.6 billion for the capture facilities in the stable commercial-government scenario.

Fig. 3.

Carbon dioxide pipeline networks for the two pipeline financing scenarios with stable, viable systems. (Upper) Commercial-government pipeline financing scenario, capturing and transporting a total of 19 Mt of carbon dioxide per year. (Lower) Full-government pipeline financing scenario, capturing and transporting 28.7 Mt per year. The diameter of each segment of the pipeline network is shown. Colocated sources are summed so that the total emissions are observable. The underlying map data sources are listed in SI Appendix.

Either case would represent a significant increase in global CCUS and CO2-EOR. For context, the full-government scenario would approximately double the global total amount of anthropogenic CCUS (6). It would abate carbon dioxide emissions equivalent to ∼11 gigawatts (GW) of wind electricity generation capacity in the United States (half the total installed wind capacity in Texas) or 14 GW of solar photovoltaic capacity (two-thirds of the total installed solar capacity in California). Carbon dioxide supply to the CO2-EOR industry would increase by ∼45%, which would drive ∼200,000 barrels per day of oil production, equal to ∼2% of current domestic production. The 1,900-km-long main trunk pipeline would be more than double the length of the Cortez pipeline from Colorado to the Permian Basin, currently the world’s largest carbon dioxide pipeline, and would have equivalent diameter and flow capacity through the 1,000-km main transport trunk section (28). The 7,000-km total pipeline network would nearly double the existing total length of carbon dioxide pipelines in the United States (28). Such an expansion, if initially built with potential for increased capacity, would also help enable and accelerate future CCUS projects in regions near the pipeline.

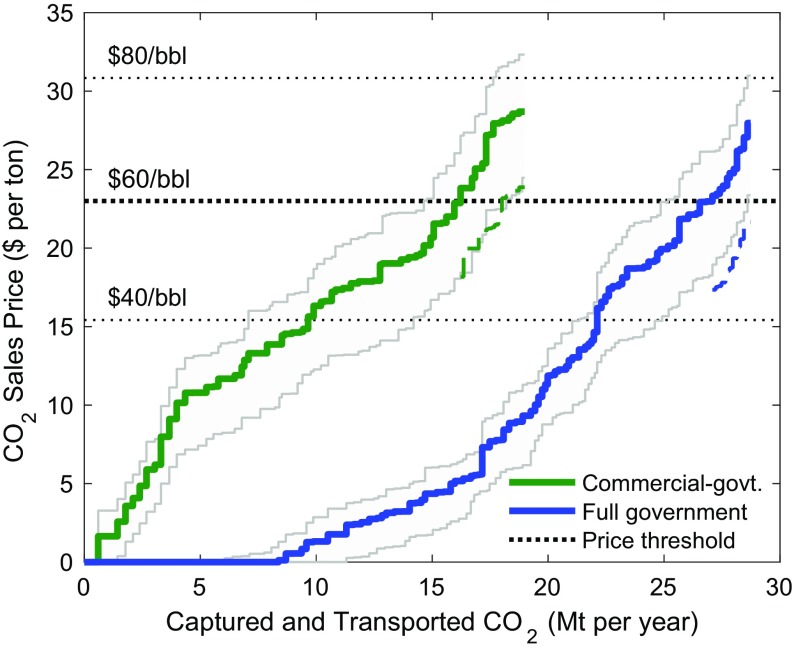

Fig. 4 shows the carbon dioxide sales prices required for each capture facility to achieve the target 15% rate of return for the stable networks of both pipeline-financing scenarios. (See Fig. 8 for the price curves for all network iterations.) Most of the sources in each scenario have required prices well below the threshold. There are also a number of marginal sources, whose required price for a 15% rate of return is above the threshold. In the latter iteration cycles, the target rate of return was 10% for these marginal sources. There are 11 marginal sources accounting for 1.6 Mt in the full-government scenario and 13 marginal sources accounting for 2.8 Mt in the commercial-government scenario. For these marginal sources, Fig. 4 also shows their required price to achieve a 10% rate of return. All marginal sources in the full-government network have a required price below the threshold for a 10% rate of return, while four marginal sources in the commercial-government scenario have a required price less than $1 above the threshold. The marginal sources are important for the viability of the system because of the strong economy of scale of pipelines: Every additional source reduces the transport cost for all other sources in the network.

Fig. 4.

Required carbon dioxide sales price curves for both pipeline financing scenarios with stable systems. Each curve shows cumulative carbon dioxide captured and transported against the required sales price for each facility. The solid curves show the required prices for each source capture facility to achieve a 15% rate of return. The dashed colored curves show the required price for the marginal sources (those with required price for 15% rate of return above the $23 per ton threshold) to achieve a 10% rate of return. Sensitivity of the systems to oil price and pipeline capital cost is also shown. The gray solid lines and shaded areas show the price curves adjusted for pipeline capital costs 10% higher to 15% lower than the core estimate. The cost sensitivity curves apply to the final stable networks to show characteristic sensitivity and are not iterated stable solutions for the higher and lower cost values. The horizontal dotted lines show the benchmark carbon dioxide sales price threshold at different oil prices, with the corresponding oil prices shown in dollars per barrel. govt., government.

The sensitivity of the stable systems to oil price and pipeline capital cost variations is also shown in Fig. 4. The sensitivity analysis uses the same optimistic-case parameters as in Table 1, but also includes pessimistic-case parameters. Two important features of system sensitivity are apparent. First, the system is most sensitive to the pipeline financing scenario and relatively more sensitive to oil price than pipeline capital cost, as was observed in Table 1. At a $60-per-barrel oil price, the 25% sensitivity range in pipeline capital cost leads to a 21% variation (relative to the core case) in the quantity of carbon dioxide below the threshold price for the commercial-government scenario and 13% for the full-government scenario. Variation of the oil price between $40 and $80 per barrel (within the price range experienced in the past 4 y) leads to a variation of 58% for the commercial-government scenario and 24% for the full-government scenario. These are substantial changes in the size of the economically viable system. This feature will cause challenges for planning investment in capture and transport systems given the volatility and unpredictability of oil prices. For this reason, carbon dioxide price stabilization contracts have been proposed as a policy measure to help enable investment in capture projects that sell carbon dioxide for CO2-EOR (34). The second important feature is that the full-government scenario system is relatively less sensitive to parameter changes than the commercial-government scenario, because it has a greater proportion of sources with required prices well below the threshold carbon dioxide sales price.

Levelized costs and revenues (the net present value per ton of carbon dioxide captured and transported) for the different financing scenarios are shown in Fig. 5. Decreasing pipeline financing costs has a strong effect on decreasing the total system cost, owing to the greater capital intensity and total capital cost of the pipelines, while a much smaller proportional reduction can be achieved by reducing ethanol biorefinery capture facility financing costs. The average levelized cost for each ton in the full-commercial scenario is greater than the levelized revenue, indicating its infeasibility, while the commercial- and full-government funding scenarios have lower average cost than revenue.

Policy Challenges and Implications

We demonstrate an opportunity to significantly expand CCUS in the United States in the near-term, spurred by the new tax credits, by targeting the lowest-cost capture opportunities and by deploying only commercially proven technologies. The pipeline network would deliver carbon dioxide to the regions of greatest demand for CO2-EOR and also connect multiple prospective long-term dedicated carbon storage resources. This would be a long-term and flexible infrastructure asset for carbon management in the United States. There are, however, a number of significant challenges to building such a CCUS network.

A key challenge to the feasibility of the CCUS networks presented here is their need for substantial additional government policy support. While the cost estimates in this study are scoping-level, and detailed engineering design and costs are needed to more precisely determine the viability of specific financing scenarios, it is clear that low-cost government financing of pipeline infrastructure would significantly reduce the required pipeline tariffs and increase the amount of economically viable capture opportunities. Government financing of carbon dioxide pipeline networks has not been prominently considered in public discussion in the United States. However, it could be the best option for initial projects if we hope to scale up CCUS as needed to achieve stated climate targets. Governments have often financed similar shared infrastructure with a public good aspect and economies of scale that are natural monopolies, such as highways, water and sewer pipelines, and telecommunications and electricity networks (54, 55). Pipelines could be financed and owned by an existing government entity, or a new government-owned utility could be created for the purpose of building carbon dioxide pipeline networks. The pipelines could be privatized when the CCUS industry is mature, as has been done for other similar infrastructure systems (49, 54).

Under any financing scenario, the timeline for building the network is formidable, since all capture facilities must begin construction before January 1, 2024, to be eligible for the tax credits. Therefore, the pipeline network would need to be constructed around that time to transport captured carbon dioxide as well as CO2-EOR projects to use the new supply. Planning, designing, permitting, and constructing the 2,000-km main trunk and 5,000 km of feeder pipelines of the full-government scenario network within this timeframe will be challenging. However, a comparison with recent natural gas pipeline development in the United States suggests that it is possible: An average of 1,500 km of new major interstate natural gas pipelines have been completed each year for the past decade, with a maximum of 4,400 km completed in a single year (56, 57). Individual major pipeline projects >200 km in length have taken 2.2 y on average from permit application filing date to construction completion (a process that begins only after the route design is completed and rights-of-way have been negotiated, which is itself a lengthy process) (56, 57). The tax-credit timelines are legislatively defined and could be changed—similar wind and solar tax credits have been extended—but this possibility cannot be planned for.

The CCUS network development would require close coordination between the ethanol and oil industries and state and federal governments, regardless of timing. A lack of coordination would leave a chicken-and-egg situation where potential capture projects are uncertain of demand and the availability of a pipeline network, while pipeline builders and CO2-EOR projects are uncertain of how much and when carbon dioxide will be available. Without a coordinated effort, we will likely see smaller-scale and more local projects that capture carbon dioxide from some of the larger ethanol biorefineries and transport it to nearer CO2-EOR or dedicated storage opportunities. Such an outcome would severely erode the viability of a large-scale network and reduce the total emissions that can be captured, since the economy of scale from combining all sources and sharing pipeline infrastructure is essential for reducing unit transport costs, as demonstrated in our network economic analysis. The ethanol industry could coordinate to cross-subsidize marginal sources to ensure the greatest total number of sources and emissions are captured (Fig. 4), thereby lowering transport tariffs for all sources.

The importance of scale demonstrated in this study will be generally important for all CCUS developments that require transportation over significant distances. The most cost-effective long-term solutions will include regionally coordinated and shared infrastructure. Pipeline infrastructure built with a long-term view will enable subsequent CCUS projects to be developed more quickly and cost-effectively. Public policy will be essential in driving infrastructure to be developed in this way. Even where carbon dioxide pipelines are commercially financed and owned, governments can ensure the infrastructure is regionally coordinated and fast-tracked. For example, the Wyoming state government’s Wyoming Pipeline Authority is preemptively securing rights-of-way permits for future carbon dioxide pipeline corridors to ease and accelerate the process for pipeline developers (28, 58).

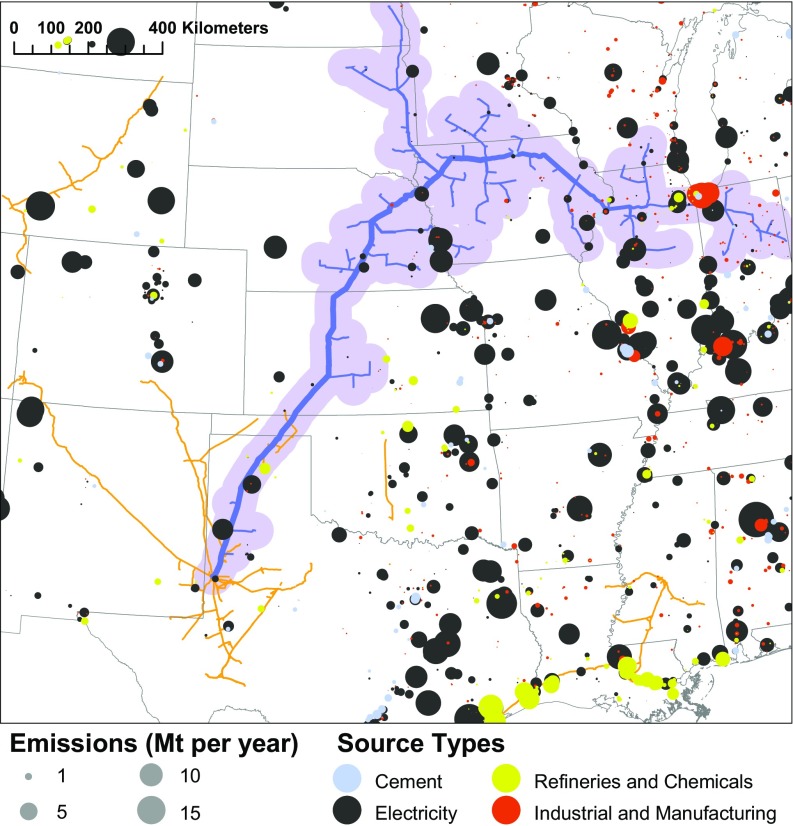

Governments could also fund additional initial capacity for pipelines to facilitate increased future CCUS, since commercial projects are not likely to significantly overbuild capacity beyond contracted carbon dioxide flow rates (49). For example, our full-government scenario main trunk pipeline has a diameter ranging from 30 inches down to 8 inches and a maximum capacity of ∼34 Mt per year. The trunk could be expanded to be a uniformly 36-inch diameter with 50 Mt per year capacity for a 30% increase in total network capital cost ($2 billion) or to 42-inch diameter with 70 Mt per year capacity for a 50% increase ($3.6 billion). Fig. 6 shows the final full-government–scenario pipeline network with other, higher-capture-cost, carbon dioxide sources that were not considered in our analysis. There are a total of 220 Mt per year emitted by existing sources within 50 km of the pipeline network. The network could also enable new build projects. For example, the region surrounding the network is the highest biomass-producing region in the United States and a prospective location for bioenergy plants with carbon capture and storage, of which ethanol is one type (45, 59). The network also coincides with the highest wind-energy–producing regions of the United States; new natural gas power plants with carbon capture could complement intermittent wind energy to decarbonize the electricity grid in these regions. There would not be capacity to subsequently add these sources without significant new capital expenditure if the pipeline network were built only to optimize for existing ethanol sources.

Fig. 6.

The full-government–scenario pipeline network is shown here with other carbon dioxide sources not considered in our analysis. The light purple area indicates 50-km proximity to the pipeline network. A number of large electricity and industrial emissions sources are located near the pipeline network. These sources are often much larger than ethanol biorefineries, as can be seen from the emissions scale. Nonethanol sources within 50 km of the pipeline network emit a combined 220 Mt per year compared with the network total of 28.7 Mt from ethanol biorefineries. Data sources are listed in SI Appendix.

The solution that can solve the challenges of financing cost, the chicken-and-egg problem, and building for long-term requirements simultaneously is for a government entity to plan and finance the pipeline network. Such a solution facilitated the successful development of wind energy in Texas, an analogous case that shared many of the characteristics and challenges of the potential CCUS network. Texas has an exceptional wind resource in the west of the state, but its population and electricity demand are mostly in the east. When wind energy became economically attractive in the mid-2000s (supported by the wind production tax credit), there was insufficient electricity-transmission capacity to transmit electricity generated in west Texas to the eastern cities and a chicken-and-egg problem between wind and transmission developers. The Texas Legislature passed a bill in 2005 ordering new electricity transmission be built to enable wind-energy development (60). The network was planned and authorized by the Public Utility Commission of Texas with consideration of future wind development requirements (61). The “Competitive Renewable Energy Zone” transmission network was completed in January 2014, which enabled the subsequent wind energy boom in Texas. The network consists of 5,800 km of new transmission lines with 11.5 GW of additional capacity, built at a cost of $6.9 billion (62). These parameters are very similar to the full-government–scenario CCUS network, including equivalent carbon emission abatement.

A potential uncertainty for the viability of a Midwest CCUS network is the future of corn ethanol in the US energy supply. Ethanol use in transportation fuels is largely driven by the federal Renewable Fuel Standard (RFS) program (63). However, corn ethanol is often criticized for its food displacement, fertilizer use, relatively low energy return on energy input, and modest greenhouse gas benefit compared with fossil petroleum (64–66). These concerns have led to proposals to eliminate or reform the RFS (67). If the ethanol industry is significantly reduced in the next 20 y, it would not make sense to build a CCUS network based on Midwest ethanol. On the other hand, CCUS presents an opportunity for the ethanol industry. Capture and storage of fermentation carbon dioxide emissions can significantly reduce the overall greenhouse gas footprint of corn ethanol (68–70), increasing its value as a low-carbon fuel. Ethanol with CCUS could realize this value through the CCUS tax credits and through programs such as the California Low Carbon Fuel Standard (LCFS) (71), a transportation fuels carbon emissions trading scheme with average carbon credit prices in the past 2 y around $100 per ton abated (72). CCUS may be recognized under the LCFS in the near future (73). If all fermentation emissions at an ethanol biorefinery were captured and sold for EOR, the CCUS value would be $0.09 per gallon of ethanol from the $35-per-ton tax credit or around $0.21 per gallon from a $100-per-ton LCFS carbon credit. For context, the average market ethanol price was $1.50 per gallon over the past 4 y. CCUS could provide significant additional revenue streams for the ethanol industry.

This study also has implications for the structure of carbon-emissions reduction policies. Carbon capture facility owners can claim the tax credits for a period of 12 y (12). If there is no price on carbon dioxide or other supporting emissions reduction policy after their credit eligibility period, the capture facilities may cease to operate if transport and operational costs exceed the carbon dioxide CO2-EOR sales price. The capture facilities will therefore need to be financed over a maximum of 12 y and repay their capital within that time. This also implies that the pipeline network financing will not be able to assume demand beyond 12 y. Pipelines are very long-lived assets, however, and initial tariffs could be lower if they can repay capital over longer time periods. In our financing scenarios, we assumed that government bears the posttax credit policy risk and provides 20-y debt finance for the commercial- and full-government financing scenarios. Long-term confidence in emissions-reduction policy would be beneficial for reducing system costs today and maximizing deployment.

Materials and Methods

Emissions Data and Estimation.

Carbon dioxide emissions for natural gas processing, hydrogen, and ammonia sources were obtained from Environmental Protection Agency (EPA) Greenhouse Gas Reporting Protocol data for 2016 (74). We estimated the emissions from the low-capture-cost syngas process stream of hydrogen and ammonia production from reported total production emissions. We assumed that all of the reported natural gas production emissions are able to be captured at low cost. Ethanol biorefinery fermentation emissions are not reported to the EPA, so we used the stoichiometry of ethanol fermentation to estimate emissions based on biorefinery facility production capacity and reported ethanol production data available from the Renewable Fuels Association and Nebraska Energy Office (25, 26, 75). More detailed information on emissions estimation from each source type is provided in SI Appendix.

Pipeline and Capture Cost Estimation.

Pipeline costs were estimated by using the US Department of Energy National Energy Technology Laboratory (NETL) CO2 Transport Cost Model (50, 76). We selected options within the model that produced the closest results compared with published costs from two major existing carbon dioxide pipelines and industry rule-of-thumb costs. The median modeled capital cost for pipelines across all segments in the network was $118,000 per inch-mile. By comparison, a general industry rule-of-thumb cost estimate is $100,000 per inch-mile (22), which is 15% lower than the median modeled value. The industry rule-of-thumb cost was used as the lower-sensitivity case value. We implemented a Microsoft Excel macro to automate the repetitive calculation of costs for each pipeline segment in the network. We used a modified version of a macro originally developed by Dubois et al. (52).

Hydrogen and ammonia capture costs were based on published cost data from the Shell Quest hydrogen production carbon capture project, supported by cost information from the Air Products Port Arthur project and hydrogen capture cost literature (17, 20, 77). Ethanol biorefinery capture costs were estimated by using a model developed by the State CO2-EOR Deployment Work Group based on project data and input from people with direct project experience (22). We modified the model to slightly increase operational costs. The model was compared with one publicly available project cost example: The reported cost of the first stage of the ADM Decatur ethanol capture project was ∼20% less than the modeled capital cost (18). The 20% lower capital cost was used as the lower-sensitivity value. Further information on the cost models and the model spreadsheets are included in SI Appendix.

Financial Analysis.

We performed a discounted cash flow analysis of project costs and revenues for both the pipelines and capture facilities. For the pipelines, we used the discounted cash flow analysis in the NETL CO2 Transport Cost Model (50, 76). We modified the analysis to reflect the new corporate tax rate and interest tax deduction rules introduced by the Tax Cuts and Jobs Act of 2017. We added an explicit debt schedule to separate consideration of debt and equity, rather than using the default weighted average cost of capital (WACC) discount rate method. The key differing assumptions for the three pipeline financing scenarios are included in Table 2. The financial parameters for the full-commercial scenario were chosen so that the WACC was 8.3%, which is typical for major oil and gas pipeline companies (78). The debt-financing period was assumed to be 12 y for the full-commercial scenario, in line with the duration of the tax credits. Commercial finance is unlikely to be available over a longer term due to the risk of no subsequent supporting policy following the expiration of the legislated tax credits. For the commercial- and full-government scenarios, we assumed that government bears the posttax credit policy risk and provided 20-y debt finance. The debt interest rate for the commercial-government scenario was assumed to be 1% above the 20-y US Treasury bond interest rate (modeled on the Department of Energy Loan Program interest rate). For the full-government scenario, we assumed the project was 100% financed by government debt at the 20-y bond interest rate. We used the maximum 20-y bond interest rate in the past 5 y. For each pipeline financing scenario, we applied the same financing parameters to all pipelines in the network.

Table 2.

Key differing financial parameter assumptions between each of the pipeline financing scenarios

| Financing scenario | Full commercial | Commercial government | Full government |

| Debt and equity percentage, % | 50:50 | 50:50 | 100:0 |

| Equity rate of return, % | 12 | 12 | n/a |

| Debt interest rate, % | 6 | 4.5 | 3.5 |

| Debt financing period, y | 12 | 20 | 20 |

n/a, not applicable.

The capture facility financial analysis assumed 100% equity financing of the projects, since they are cash-flow negative and could not make debt repayments. The projects rely on the tax credits for their positive value. We applied the legislated schedule for the value of the tax credits in each year (12). We assumed the project owners could fully monetize the value of the tax credits. The target rate of return for the capture facilities was 15%, but a 10% minimum rate of return was used for marginal facilities after the first network iteration cycle. The capture facilities have a higher target rate of return than the pipelines since they are less established industries, with revenue more closely tied to oil prices and, therefore, have higher risk.

All pipeline and hydrogen-capture projects were assumed to begin in 2020 with a 4-y capital expenditure period. Ethanol capture projects were assumed to begin in 2022 with a 2-y capital expenditure period. All projects become operational in 2024. We assumed 2% inflation for all costs and the carbon dioxide sales price. All costs are reported in US 2018 dollars. Further information on the financial analysis, a full list of assumptions, and the financial analysis model spreadsheets are all included in SI Appendix.

Network Economic Analysis.

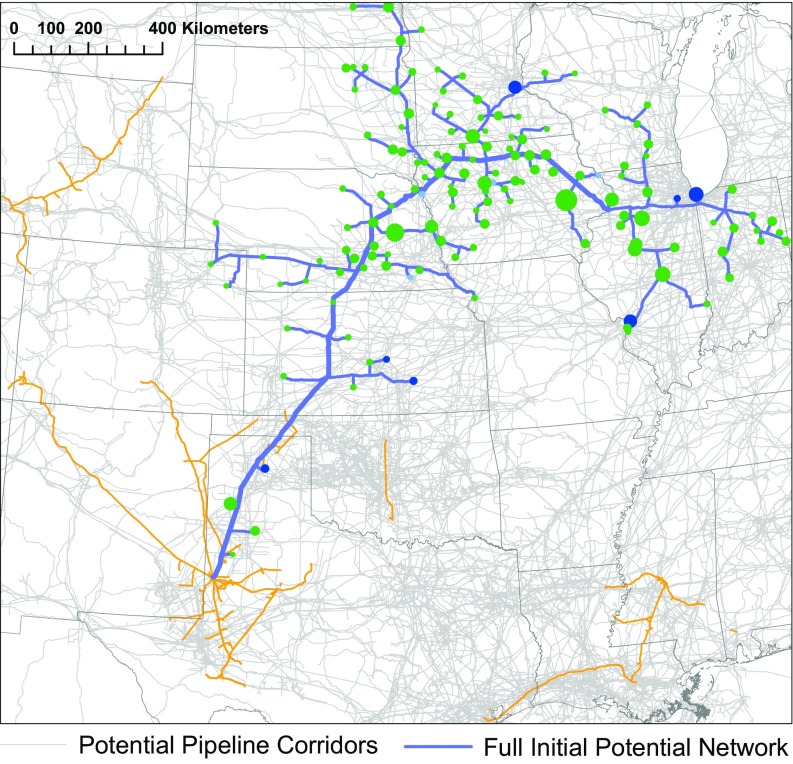

We initially considered all of the low-capture-cost sources in the study area with emissions exceeding the 100,000 tons per year minimum for tax-credit eligibility, shown in Fig. 7. The first step in the network analysis was to analyze the trunk options, shown in Fig. 2, as described in Results and Discussion and SI Appendix. After determining the best trunk route option, a pipeline network collecting carbon dioxide from all sources was designed; the full initial network is shown in Fig. 7. All network design was performed with Esri ArcGIS. We limited potential pipeline routes to existing natural gas, ammonia, and carbon dioxide pipelines, as well as railways, interstate highways, and high-voltage electricity transmission lines. The geographic information system (GIS) source data are listed in SI Appendix. We used the ArcGIS Network Analyst feature to find the shortest routes from each source to the Permian Basin destination, with manual constraints employed so that sources would aggregate efficiently and follow the trunk pipeline routes. The detailed ArcGIS methodology is included in SI Appendix.

Fig. 7.

The full initial network and sources considered in the analysis. The total capture potential is 37 Mt per year. The map also shows the potential pipeline corridors considered, which included existing natural gas, ammonia, and carbon dioxide pipelines, as well as railways, interstate highways, and high-voltage electricity transmission lines. The sources of the underlying map data are listed in SI Appendix.

After determining the initial network design, we performed the financial analysis and network iteration process to find the stable, economically viable networks for each financing scenario. The process was as follows:

(i) Determine the carbon dioxide flow rate for each segment of the pipeline network.

(ii) Calculate the pipeline size, costs, and required carbon dioxide transport tariffs using the modified NETL CO2 Transport Cost Model (50, 52, 76). Calculate the tariff that each source must pay based on the pipeline segments it uses.

(iii) Calculate the required carbon dioxide sales price for each source using the capture facility financial analysis model, with the pipeline tariff input from the previous step.

(iv) Eliminate all sources with a required carbon dioxide sales price above the $23 per ton threshold. A threshold requiring 15% rate of return at $23 per ton was used in the first iteration. Subsequent iterations allowed a 10% rate of return for marginal facilities, as explained in Results and Discussion.

(v) Update the pipeline network design (if required).

(vi) Repeat steps i–v until a stable system is found with all sources economically viable.

More detail on the network economic analysis methodology is included in SI Appendix. The network analysis was performed separately for each pipeline financing scenario. The required carbon dioxide sales price curves for each iteration of each financing scenario are shown in Fig. 8.

Supplementary Material

Acknowledgments

We thank Daniel Sanchez for clarification of the FUTURE Act legislative language; Judith Greenwald, Denise Mauzerall, and Rob Socolow for early review; Jeff Brown for education on energy project financing; Wangyal Shawa for GIS support; and Martin Dubois and Dane McFarlane for provision of the pipeline cost model automation macro. This work was supported in part by the Carbon Mitigation Initiative at Princeton University; the Princeton Environmental Institute through the Princeton Environmental Institute Program in Science, Technology, and Environmental Policy Fellowship funded under the Perkins endowment; and the Andlinger Center for Energy and the Environment at Princeton University through the Maeder Fellowship.

Footnotes

The authors declare no conflict of interest.

This article is a PNAS Direct Submission.

This article contains supporting information online at www.pnas.org/lookup/suppl/doi:10.1073/pnas.1806504115/-/DCSupplemental.

References

- 1.Intergovernmental Panel on Climate Change . Technical summary. In: Edenhofer O, et al., editors. Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge Univ Press; Cambridge, UK: 2014. [Google Scholar]

- 2.International Energy Agency . Energy Technology Perspectives 2017. International Energy Agency; Paris: 2017. [Google Scholar]

- 3.Fuss S, et al. Betting on negative emissions. Nat Clim Chang. 2014;4:850–853. [Google Scholar]

- 4.Sanchez DL, Nelson JH, Johnston J, Mileva A, Kammen DM. Biomass enables the transition to a carbon-negative power system across western North America. Nat Clim Chang. 2015;5:230–234. [Google Scholar]

- 5.Peters GP, et al. Key indicators to track current progress and future ambition of the Paris Agreement. Nat Clim Chang. 2017;7:118–122. [Google Scholar]

- 6.Global CCS Institute . Projects Database: Large-Scale CCS Facilities. Global CCS Institute; Melbourne: 2017. [Google Scholar]

- 7.Mac Dowell N, Fennell PS, Shah N, Maitland GC. The role of CO2 capture and utilization in mitigating climate change. Nat Clim Chang. 2017;7:243–249. [Google Scholar]

- 8.Shell . Sky Scenario: Meeting the Goals of the Paris Agreement. Royal Dutch Shell plc; The Hague: 2018. [Google Scholar]

- 9.International Energy Agency . Tracking Clean Energy Progress 2017. International Energy Agency; Paris: 2017. [Google Scholar]

- 10.Rogelj J, et al. Paris Agreement climate proposals need a boost to keep warming well below 2 °C. Nature. 2016;534:631–639. doi: 10.1038/nature18307. [DOI] [PubMed] [Google Scholar]

- 11.International Energy Agency . 20 Years of Carbon Capture and Storage: Accelerating Future Deployment. International Energy Agency; Paris: 2016. [Google Scholar]

- 12.Heitkamp H. 2017. S.1535, 115th Congress: FUTURE Act.

- 13.Kuuskraa VA, Van Leeuwen T, Wallace M. Improving Domestic Energy Security and Lowering CO2 Emissions with “Next Generation” CO2-Enhanced Oil Recovery (CO2-EOR) National Energy Technology Laboratory; Pittsburgh: 2011. [Google Scholar]

- 14.Hill B, Hovorka S, Melzer S. Geologic carbon storage through enhanced oil recovery. Energy Procedia. 2013;37:6808–6830. [Google Scholar]

- 15.Rubin ES, Davison JE, Herzog HJ. The cost of CO2 capture and storage. Int J Greenh Gas Control. 2015;40:378–400. [Google Scholar]

- 16.National Energy Technology Laboratory . Cost and Performance Baseline for Fossil Energy Plants Volume 1a: Bituminous Coal (PC) and Natural Gas to Electricity, Revision 3. US Department of Energy, National Energy Technology Laboratory; Pittsburgh: 2015. [Google Scholar]

- 17.Shell 2017. Quest Carbon Capture and Storage Project Annual Summary Report—Alberta Department of Energy: 2016 (Shell Canada Energy, Calgary, Alberta, Canada)

- 18.McKaskle R. 2016 Midwest Carbon Sequestration Science Conference. Midwest Geological Sequestration Consortium; Champaign, IL: 2016. Insights into costs of CCS gained from the IBDP. [Google Scholar]

- 19.Leeson D, Mac Dowell N, Shah N, Petit C, Fennell PS. A Techno-economic analysis and systematic review of carbon capture and storage (CCS) applied to the iron and steel, cement, oil refining and pulp and paper industries, as well as other high purity sources. Int J Greenh Gas Control. 2017;61:71–84. [Google Scholar]

- 20.International Energy Agency Greenhouse Gas R&D Programme 2017. Techno-Economic Evaluation of SMR Based Standalone (Merchant) Hydrogen Plant with CCS (International Energy Agency Greenhouse Gas R&D Programme, Cheltenham, UK)

- 21.National Energy Technology Laboratory 2014. Cost of Capturing CO2 from Industrial Sources (US Department of Energy National Energy Technology Laboratory, Pittsburgh)

- 22.State CO2-EOR Deployment Work Group 2017. Capturing and Utilizing CO2 from Ethanol: Adding Economic Value and Jobs to Rural Economies and Communities While Reducing Emissions (Great Plains Institute, Minneapolis)

- 23.Gollakota S, McDonald S. Commercial-scale CCS project in Decatur, Illinois–Construction status and operational plans for demonstration. Energy Procedia. 2014;63:5986–5993. [Google Scholar]

- 24.Environmental Protection Agency 2018 Greenhouse gas reporting program: Capture, supply, and underground injection of carbon dioxide (Environmental Protection Agency, Washington, DC). Available at https://www.epa.gov/ghgreporting/capture-supply-and-underground-injection-carbon-dioxide. Accessed February 15, 2018.

- 25.Renewable Fuels Association 2018 Ethanol Biorefinery Locations (Renewable Fuels Association, Washington, DC). Available at https://www.ethanolrfa.org/resources/biorefinery-locations/. Accessed February 7, 2018.

- 26.Nebraska Energy Office 2018 Ethanol Facilities Capacity by State and Plant (Nebraska Energy Office, Lincoln, NE). Available at www.neo.ne.gov/statshtml/122.htm. Accessed February 7, 2018.

- 27.Finley RJ. An overview of the Illinois basin–Decatur project. Greenhouse Gases-Science Technol. 2014;4:571–579. [Google Scholar]

- 28.Wallace M, Goudarzi L, Callahan K, Wallace R. 2015. A Review of the CO2 Pipeline Infrastructure of the U.S (US Department of Energy National Energy Technology Laboratory, Pittsburgh)

- 29.Godec ML, Kuuskraa VA, Dipietro P. Opportunities for using anthropogenic CO2 for enhanced oil recovery and CO2 storage. Energy Fuels. 2013;27:4183–4189. [Google Scholar]

- 30.International Energy Agency 2015. Storing CO2 Through Enhanced Oil Recovery: Combining EOR with CO2 Storage (EOR+) for Profit (International Energy Agency, Paris)

- 31.Middleton RS, et al. Jumpstarting commercial-scale CO2 capture and storage with ethylene production and enhanced oil recovery in the US Gulf. Greenhouse Gases-Science Technol. 2015;5:241–253. [Google Scholar]

- 32.Godec ML. 2014 Carbon dioxide enhanced oil recovery: Industrial CO2 supply crucial for EOR. The American Oil & Gas Reporter. Available at https://www.aogr.com/magazine/editors-choice/industrial-co2-supply-crucial-for-eor. Accessed March 25, 2018.

- 33.Gray L, Goodyear SG. Abu Dhabi International Petroleum Exhibition and Conference. Society of Petroleum Engineers; Abu Dhabi, United Arab Emirates: 2014. Overcoming the CO2 supply challenge for CO2 EOR. [Google Scholar]

- 34.State CO2-EOR Deployment Work Group 2016. Putting the Puzzle Together: State & Federal Policy Drivers for Growing America’s Carbon Capture & CO2-EOR Industry (Great Plains Institute, Minneapolis)

- 35.International Energy Agency 2018 Commentary: US Budget Bill May Help Carbon Capture Get Back on Track (International Energy Agency, Paris). Available at https://www.iea.org/newsroom/news/2018/march/commentary-us-budget-bill-may-help-carbon-capture-get-back-on-track.html. Accessed March 20, 2018.

- 36.Environmental Protection Agency 2010. Fact Sheet for Geologic Sequestration and Injection of Carbon Dioxide: Subparts RR and UU (Environmental Protection Agency, Washington, DC)

- 37.Kuuskraa VA, Godec ML, Dipietro P. CO2 utilization from “next generation” CO2 enhanced oil recovery technology. Energy Procedia. 2013;37:6854–6866. [Google Scholar]

- 38.Cooney G, Littlefield J, Marriott J, Skone TJ. Evaluating the climate benefits of CO2-enhanced oil recovery using life cycle analysis. Environ Sci Technol. 2015;49:7491–7500. doi: 10.1021/acs.est.5b00700. [DOI] [PubMed] [Google Scholar]

- 39.Azzolina NA, et al. How green is my oil? A detailed look at greenhouse gas accounting for CO2-enhanced oil recovery (CO2-EOR) sites. Int J Greenh Gas Control. 2016;51:369–379. [Google Scholar]

- 40.Middleton RS, Bielicki JM. A scalable infrastructure model for carbon capture and storage: SimCCS. Energy Policy. 2009;37:1052–1060. [Google Scholar]

- 41.Middleton RS, Kuby MJ, Wei R, Keating GN, Pawar RJ. A dynamic model for optimally phasing in CO2 capture and storage infrastructure. Environ Model Softw. 2012;37:193–205. [Google Scholar]

- 42.Kuby MJ, Bielicki JM, Middleton RS. Optimal spatial deployment of CO2 capture and storage given a price on carbon. Int Reg Sci Rev. 2011;34:285–305. [Google Scholar]

- 43.Johnson N, Ogden J. Detailed spatial modeling of carbon capture and storage (CCS) infrastructure deployment in the southwestern United States. Energy Procedia. 2011;4:2693–2699. [Google Scholar]

- 44.Middleton RS, Kuby MJ, Bielicki JM. Generating candidate networks for optimization: The CO2 capture and storage optimization problem. Comput Environ Urban Syst. 2012;36:18–29. [Google Scholar]

- 45.Johnson N, Parker N, Ogden J. How negative can biofuels with CCS take us and at what cost? Refining the economic potential of biofuel production with CCS using spatially-explicit modeling. Energy Procedia. 2014;63:6770–6791. [Google Scholar]

- 46.Sanchez DL, Johnson N, McCoy ST, Turner PA, Mach KJ. Near-term deployment of carbon capture and sequestration from biorefineries in the United States. Proc Natl Acad Sci USA. 2018;115:4875–4880. doi: 10.1073/pnas.1719695115. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Kolster C, Masnadi MS, Krevor S, Mac Dowell N, Brandt AR. CO2 enhanced oil recovery: A catalyst for gigatonne-scale carbon capture and storage deployment? Energy Environ Sci. 2017;10:2594–2608. [Google Scholar]

- 48.Dai Z, et al. An integrated framework for optimizing CO2 sequestration and enhanced oil recovery. Environ Sci Technol Lett. 2014;1:49–54. [Google Scholar]

- 49.State CO2-EOR Deployment Work Group 2017. 21st Century Energy Infrastructure: Policy Recommendations for Development of American CO2 Pipeline Networks (Great Plains Institute, Minneapolis)

- 50.National Energy Technology Laboratory . FE/NETL CO2 Transport Cost Model: Description and User’s Manual. US Department of Energy National Energy Technology Laboratory; Pittsburgh: 2018. [Google Scholar]

- 51.Kesicki F, Ekins P. Marginal abatement cost curves: A call for caution. Clim Policy. 2012;12:219–236. [Google Scholar]

- 52.Dubois MK, McFarlane D, Bidgoli TS. 2017 Mastering the Subsurface Through Technology Innovation, Partnerships and Collaboration: Carbon Storage and Oil and Natural Gas Technologies Review Meeting. US Department of Energy National Energy Technology Laboratory; Pittsburgh: 2017. CO2 pipeline cost analysis utilizing a modified FE/NETL CO2 transport cost model tool. [Google Scholar]

- 53.State CO2-EOR Deployment Work Group 2017. 21st Century Energy Infrastructure: Federal Financing Options to Support Buildout of Carbon Dioxide Pipelines (Great Plains Institute, Minneapolis)

- 54.Chan C, Forwood D, Roper H, Sayers C. Public Infrastructure Financing: An International Perspective. Australian Government Productivity Commission; Melbourne: 2009. [Google Scholar]

- 55.Gramlich EM. Infrastructure investment: A review essay. J Econ Lit. 1994;32:1176–1196. [Google Scholar]

- 56.Federal Energy Regulatory Commission 2018 Approved Major Pipeline Projects (Federal Energy Regulatory Commission, Washington, DC). Available at https://www.ferc.gov/industries/gas/indus-act/pipelines/approved-projects.asp. Accessed April 1, 2018.

- 57.Energy Information Administration 2018 Natural Gas Pipeline Projects (US Energy Information Administration, Washington, DC). Available at https://www.eia.gov/naturalgas/data.php#pipelines. Accessed April 1, 2018.

- 58.Wyoming Pipeline Authority . Wyoming Pipeline Corridor Initiative Plan of Development. Wyoming Pipeline Authority; Casper, WY: 2014. [Google Scholar]

- 59.Baik E, et al. Geospatial analysis of near-term potential for carbon-negative bioenergy in the United States. Proc Natl Acad Sci USA. 2018;115:3290–3295. doi: 10.1073/pnas.1720338115. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 60.Nelson J. 2005. SB 20, 84th Legislature.

- 61.Staine RR. CREZ II, coming soon to a Windy Texas plain near you? Encouraging the Texas renewable energy industry through transmission investment. Tex Law Rev. 2014;93:521–556. [Google Scholar]

- 62.Lashner W. Quadrennial Energy Review Public Meeting: State, Local and Tribal Issues. US Department of Energy; Santa Fe, NM: 2014. The competitive renewable energy zones process. [Google Scholar]

- 63.Environmental Protection Agency 2018 Renewable fuel standard program (Environmental Protection Agency, Washington, DC). Available at https://www.epa.gov/renewable-fuel-standard-program. Accessed March 25, 2018.

- 64.Searchinger T, et al. Use of U.S. croplands for biofuels increases greenhouse gases through emissions from land-use change. Science. 2008;319:1238–1240. doi: 10.1126/science.1151861. [DOI] [PubMed] [Google Scholar]

- 65.Tilman D, et al. Energy. Beneficial biofuels—the food, energy, and environment trilemma. Science. 2009;325:270–271. doi: 10.1126/science.1177970. [DOI] [PubMed] [Google Scholar]

- 66.Hill J, Nelson E, Tilman D, Polasky S, Tiffany D. Environmental, economic, and energetic costs and benefits of biodiesel and ethanol biofuels. Proc Natl Acad Sci USA. 2006;103:11206–11210. doi: 10.1073/pnas.0604600103. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 67.Holman CM. Setbacks in implementing the renewable fuel standard lead to calls for reform. Biotechnol Law Rep. 2016;35:249–257. [Google Scholar]

- 68.Laude A, Ricci O, Bureau G, Royer-Adnot J, Fabbri A. CO2 capture and storage from a bioethanol plant: Carbon and energy footprint and economic assessment. Int J Greenh Gas Control. 2011;5:1220–1231. [Google Scholar]

- 69.Hornafius KY, Hornafius JS. Carbon negative oil: A pathway for CO2 emission reduction goals. Int J Greenh Gas Control. 2015;37:492–503. [Google Scholar]

- 70.Flugge M, et al. 2017. A life-cycle analysis of the greenhouse gas emissions of corn-based ethanol (US Department of Agriculture, Washington, DC)

- 71.Yeh S, Witcover J, Lade GE, Sperling D. A review of low carbon fuel policies: Principles, program status and future directions. Energy Policy. 2016;97:220–234. [Google Scholar]

- 72.California Air Resources Board . Monthly LCFS Credit Transfer Activity Reports. California Air Resources Board; Sacramento, CA: 2018. [Google Scholar]

- 73.California Air Resources Board . Draft Accounting and Permanence Protocol for Carbon Capture and Geologic Sequestration Under Low Carbon Fuel Standard. California Air Resources Board; Sacramento, CA: 2017. [Google Scholar]

- 74.Environmental Protection Agency . Greenhouse Gas Reporting Program. Environmental Protection Agency; Washington, DC: 2017. [Google Scholar]

- 75.Renewable Fuels Association 2018 Industry Statistics (Renewable Fuels Association, Washington, DC). Available at https://www.ethanolrfa.org/resources/industry/statistics/. Accessed February 7, 2018.

- 76.National Energy Technology Laboratory . FE/NETL CO2 Transport Cost Model. US Department of Energy National Energy Technology Laboratory; Pittsburgh: 2018. [Google Scholar]

- 77.National Energy Technology Laboratory . Air Products and Chemicals, Inc.: Demonstration of CO2 Capture and Sequestration of Steam Methane Reforming Process Gas Used for Large Scale Hydrogen Production. US Department of Energy National Energy Technology Laboratory; Pittsburgh: 2017. [Google Scholar]

- 78.Damodaran A. 2018 Cost of Capital by Sector (New York University Stern School of Business, New York). Available at people.stern.nyu.edu/adamodar/New_Home_Page/datafile/wacc.htm. Accessed July 10, 2018.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.