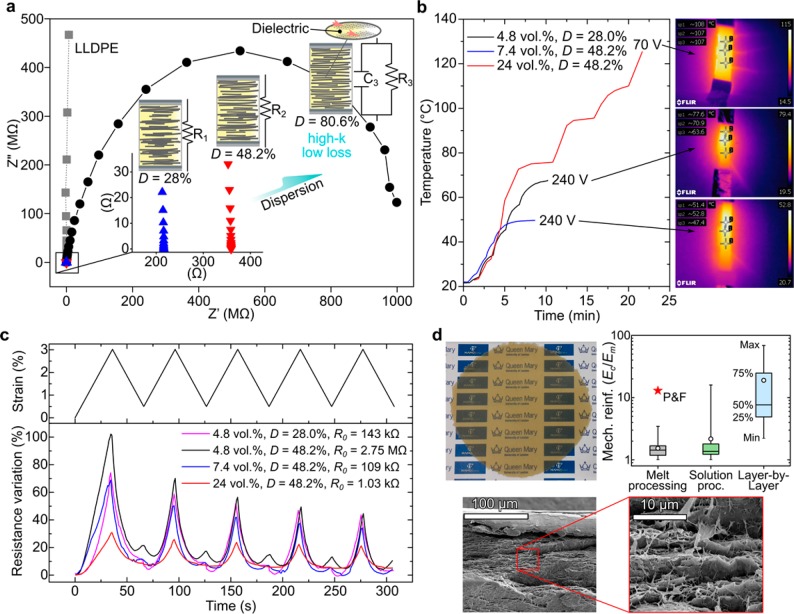

Figure 4.

Examples of nanocomposites with optimized microstructures (nanofiller dispersion) for a variety of applications. (a) Imaginary (Z′′) vs real impedance (Z′) obtained from electrochemical impedance spectroscopy of LLDPE containing 4.8 vol % GNP for different dispersion levels. In accordance with value of σth expected from eq 5 the sample with D = 80.6% is the only one showing a capacitive effect, demonstrated by the Nyquist semicircle. (b) Self-heating originating from the Joule effect of LLDPE composites at different GNP loadings and dispersion levels. The sample with 4.8 vol % GNP shows a better self-heating effect than the sample containing 7.4 vol % GNP because its nanofiller dispersion level (D = 28) is closer to the critical value Dc= 25% predicted by eq 5. (c) Strain sensing of LLDPE composites with different GNP loadings and dispersion levels. High values of D give high resistance variations (gauge factor of ∼30) because the nanocomposite conductivity approaches the theoretical value σth more quickly with the strain (see sample containing 4.8 vol % GNP with D = 48.2%). Dispersions closer to Dc provide better electrical signals. The resistance variation becomes less evident for increasing amounts of GNP because the difference between σM and σth is smaller (for details, see section S.12.2 in the Supporting Information). (d) Optical picture (top left) of LLDPE containing 70 wt % MMT (∼10 cm wide and ∼400 μm thick), SEM cross-sections (bottom), and comparison (top right) of mechanical reinforcement with literature values for MMT nanocomposites grouped by the processing method. We achieved the highest mechanical reinforcement ever reported for melt processing. The QMUL logo is used with permission.