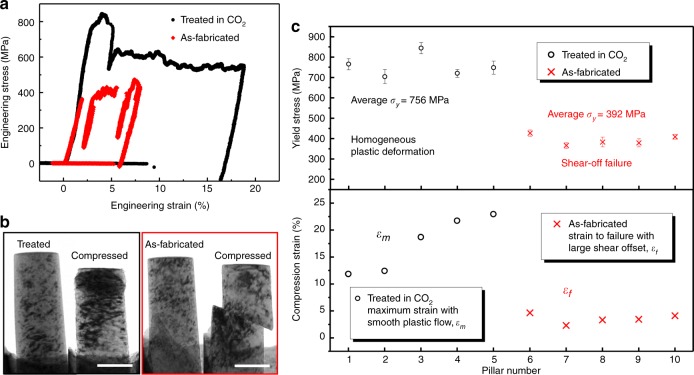

Fig. 5.

Effect of the treated surface layer on the mechanical properties of the samples. a Typical compressive engineering stress-strain curves of an as-fabricated Mg pillar (red) and a pillar treated in CO2 (black). Note both the yield stress and plastic deformation ability are improved significantly. b Bright-field TEM images of the Mg pillar treated in CO2 (framed in black) and an as-fabricated Mg pillar (framed in red) before and after compression. The MgCO3 protective layer showed great adhesion to its substrate and excellent compatible deformation capability. c Statistics of the yield stress and compressive strain vs. the Mg pillars. Different from those as-fabricated Mg pillars that fail with large shear offset, the pillars with MgCO3 protective layer deform homogeneously with smooth plastic flow with the maximus compressive strain up to 22%. The error bars are two standard deviations. Scale bars, 200 nm