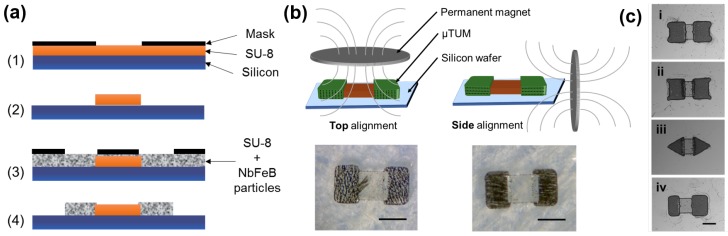

Figure 5.

Fabrication process of microscale magnetic tumbling motors (TUM). (a) Photolithography process followed for the the fabrication of TUM. (b) Magnetic particle alignment techniques. Magnets located above the robot result in alignment along the geometric z-axis and sideways tumbling (ST); magnets located beside the robot result in alignment along the geometric x-axis and lengthwise tumbling (LT). (c) Optical images of the different geometric variations on the TUM ending sections that have been explored: (i) rounded corners, (ii) sharp corners, (iii) triangles and (iv) (asymmetric) rounded rectangles. Scale bar, 300 m.