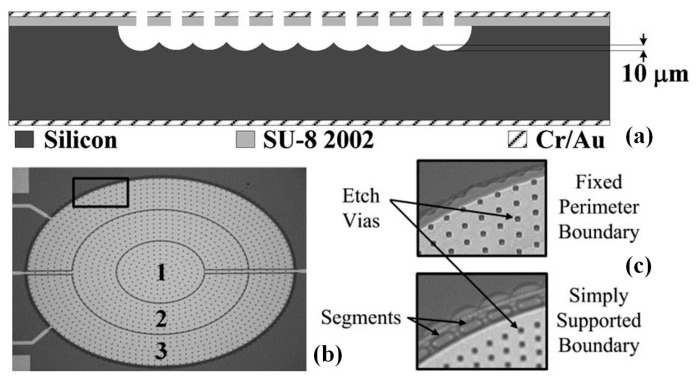

Figure 13.

Micromachined deformable membrane mirrors for confocal microscope. (a) Cross section of the process-3 SU-8 2002 mirrors, which are dry etch released in XeF2: 2.5 μm of SU-8 2002 is photopatterned; 60-Å chrome and 150-nm gold are evaporated as a reflective coating and to form the top electrodes, patterned using a liftoff process; 60-Å chrome and 200-nm gold are evaporated onto the backside for the silicon counter electrode; and an air gap is created by dry etching the silicon through the small vias. (b) Top view of a 2 mm × 2.8 mm elliptical boundary mirror with the three electrodes labeled; (c) Smaller section of the mirror with either a fixed perimeter boundary or with 20% duty width segments in the membrane layer to emulate a simply supported boundary, and 3- or 5-μm square vias allow etchants to release the mirrors (Reproduced with permission from IEEE [88]).