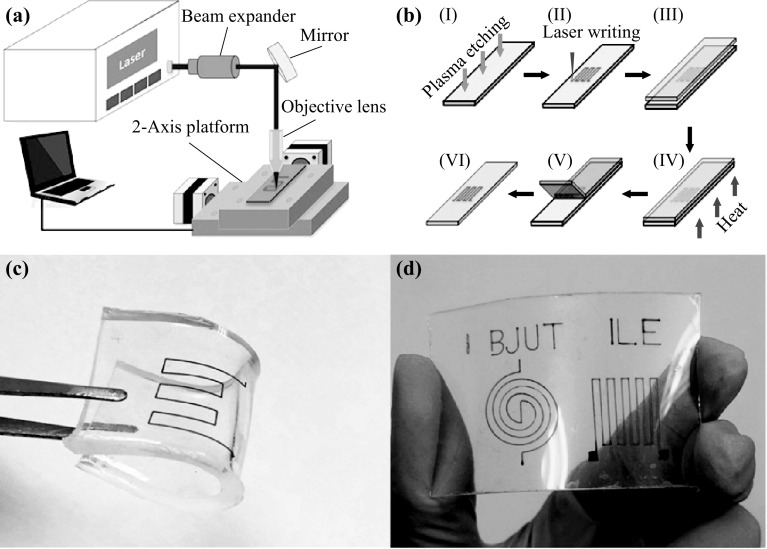

Fig. 1.

a Schematic of the experimental setup for laser direct writing. The laser beam is directed at a collimator. Afterward the beam is reflected by a mirror and focused by a microscope objective (NA = 0.3). The translation stage enables the accurate and repeatable positioning of the substrate in two dimensions, with an overall accuracy of about 500 nm. b Schematic illustration of the fabrication of the flexible sensor based on copper electrode: (I) oxygen plasma etching of the surface of the glass, (II) laser writing of copper salt, (III) coating of PDMS onto a reduced copper electrode, (IV) curing of the PDMS-covered substrate, (V) peeling off the PDMS strip from the substrate, (VI) overlay of the PDMS on a target substrate. c Photograph of copper electrode on PDMS substrate. d Spider and zigzag electrodes on PET substrate