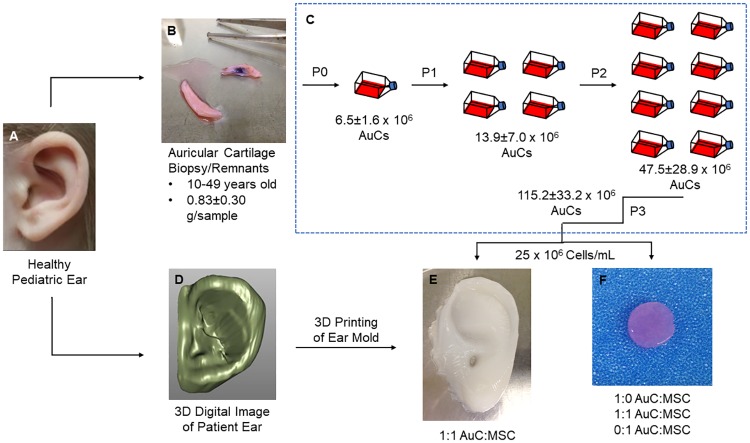

Fig 1. Human auricular cartilage engineering process.

(A) High-resolution images of a pediatric ear were rapidly scanned, while human auricular cartilage was obtained from healthy donors. (B) The remnants of otoplasty procedures were cleaned of perichondrium and damaged tissue before digestion in collagenase. (C) Human AuCs were plated and expanded through passage 3. All data shown ± SD. (D) Images of the patient ear were converted to a continuous digital surface and edited to remove noise and enhance definition of external features. (E) Human AuCs were combined in a 1:1 ratio with human MSCs, encapsulated in type I collagen, and injected into patient-specific molds which were 3D printed based on the digital images. (F) Human AuCs and human MSCs were combined in ratios of 1:0, 1:1, and 0:1 AuC:MSC, encapsulated in type I collagen, and polymerized to form disc constructs 8 mm in diameter and 2 mm in thickness.