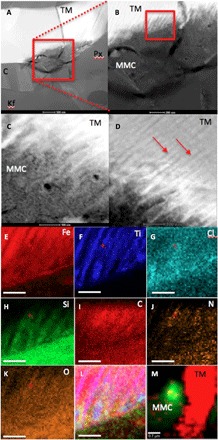

Fig. 2. High-resolution TEM analysis of magnetite and MMC features within the Nakhla meteorite.

(A to D) High-angle annular dark-field (HAADF) TEM images showing (A) a Nakhla titano-magnetite (TM) grain extracted through FIB milling from the area marked with a red box in Fig. 1 (C and D). The grain is surrounded by pyroxene (Px), K-feldspar (Kf), and cristobalite (C) (scale bar, 500 nm). (B) A higher-magnification image of the red boxed area in (A), showing evidence of corrosion with a comb-like etching pattern into the TM grain (TM; scale bar, 200 nm). (C) A higher-magnification and high-contrast image of the area denoted by the red box in (B), with the titanium-rich exsolution lamellae in the TM corroded grain visible (red arrows; scale bar, 100 nm). (D) Area showing the interaction with TM exsolution lamellae and the surrounding matrix; the titanium-rich lamellae are highlighted with red arrows; EDX and selected-area electron diffraction (SAED) analyses of this matrix revealed a carbon-rich but amorphous (no diffraction contrast detected during tilting of the sample) assemblage (MMC; scale bar, 100 nm). (E to K) X-ray intensity maps of the exsolution features from the red box in (B), showing the distribution and associations between (scale bars, 100 nm). (E) Iron, (F) titanium, (G) chlorine, (H) silicon, (I) carbon, (J) nitrogen, and (K) oxygen, while (L) is a three-color composite map of Fe (red), Ti (blue), and Cl (green) to show the link between the corrosion of the TM grain and a chlorine-rich brine. (M) Composite CRIS map of the FIB section after TEM analysis showing titano-magnetite (red) and MMC (green), confirming the presence of MMC before and after analysis by TEM [note that map (M) is rotated and at a lower magnification compared with the x-ray maps in (A) to (L) and fig. S1; scale bar, 0.7 μm].