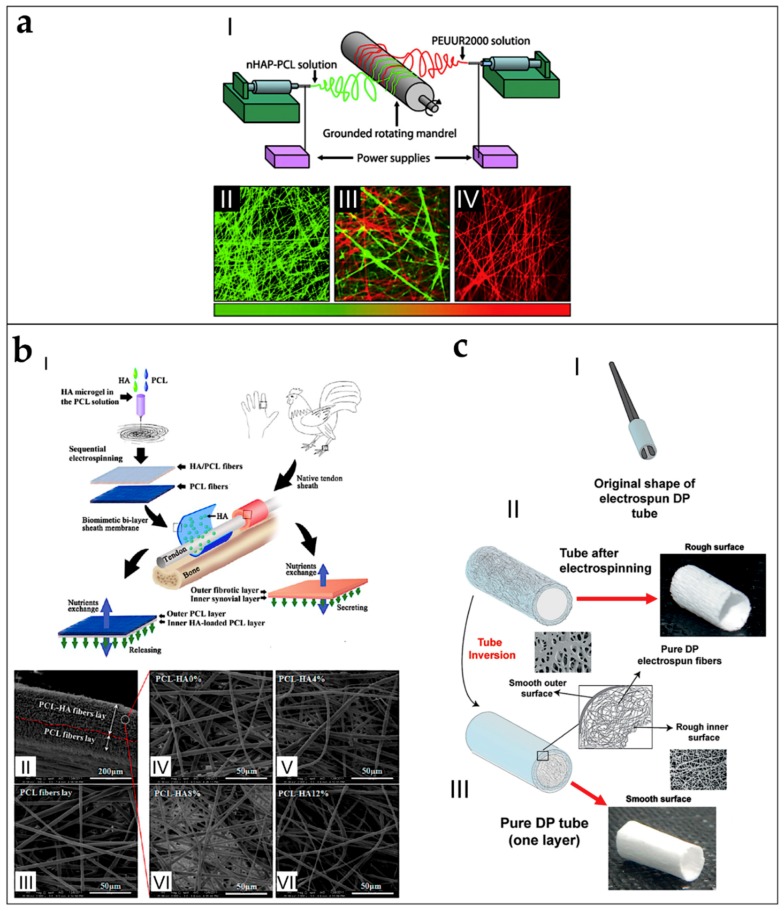

Figure 14.

Schematic workflows to produce electrospun scaffolds suitable for tendon/ligament-to-bone attachment or for tendon and ligament healing and anti-adhesion applications. (a) Co-electrospun random mats with gradient of PEUUR2000 and PCL, loaded with nanohydroxyapatite (HAp) for ligament-to-bone regeneration (adapted from Samavedi et al. [110], reproduced with permission. Copyright 2011, Elsevier): (I) co-electrospinning setup to obtain nanofibrous mats with gradient on a rotating drum collector; (II) fluorescent image of the HAp-PCL nanofibers side; (III) fluorescent image of the transition region of the two nanofiber sides; and (IV) fluorescent image of the PEUUR2000 nanofibers side. (b) Double layer electrospun mat of random PCL and a blend of PCL/HA for tendon healing (adapted with permission from Liu et al. [113]. Copyright 2012, American Chemical Society): (I) electrospinning setup and in-situ application of the scaffold; (II) SEM section of the bilayer scaffold; (III) PCL nanofibers; and (IV–VII) layers of HA/PCL nanofibers with different percentages of HA. (c) Production process to obtain a nanofibrous tube or conduit of DP for tendon healing and anti-adhesion applications (adapted from Evrova et al. [127], reproduced with permission. Copyright 2016, John Wiley and Sons); (I) after the nanofibers are electrospun on a rotating drum collector, the tube is removed from it; (II) structure and images of the tube immediately after the movement from the drum collector; and (III) structure and images of the tube after is inversion.