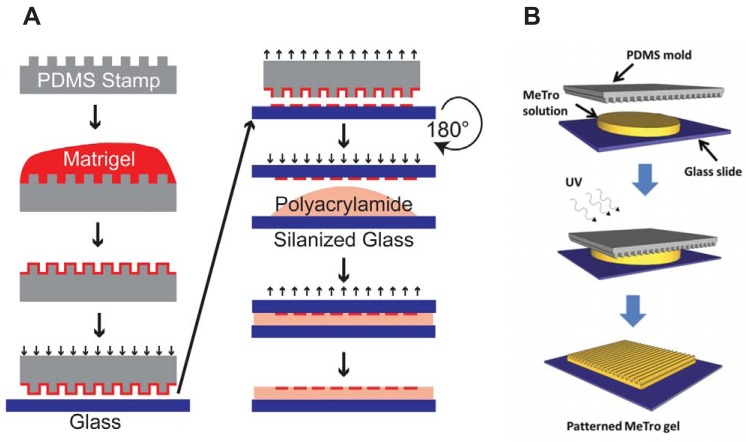

Fig. 2.

Dictating two-dimensional tissue architecture with substrate micropatterning. Customizable polydimethylsiloxane (PDMS) stamps (gray) are fabricated with photolithography and soft lithography. A: in one example of microcontact printing, stamps are coated with proteins (red) such as Matrigel and inverted onto glass coverslips (blue), transferring the pattern to the coverslip. These patterned coverslips are inverted onto polyacrylamide hydrogel prepolymer solution to transfer the extracellular matrix protein pattern to the hydrogel as it polymerizes. B: micromolding is performed by inverting PDMS stamps onto a hydrogel prepolymer solution (yellow) such as methacrylated tropoelastin (MeTro). The stamp remains in position during hydrogel polymerization, which is initiated by ultraviolet (UV) light in this example, to mold the pattern from the PDMS stamp into the hydrogel. Images were adapted from Ref. 146 with permission from the National Academy of Sciences (A) and from Ref. 8 with permission from John Wiley & Sons (B).