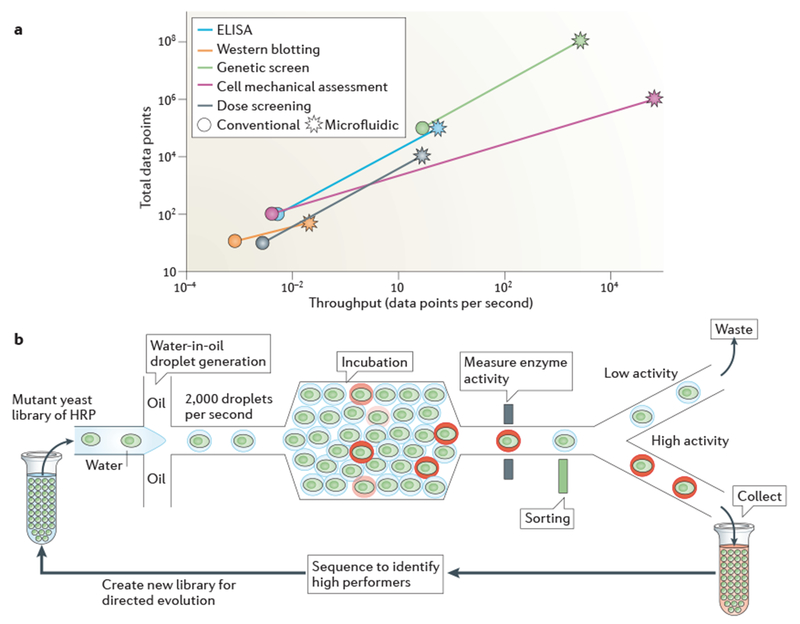

Figure 4 |. High-throughput microfluidics.

a | Integrating sample processing and analysis steps within microfluidic technologies has increased the throughput and data output of a range of analytical tools to orders of magnitude higher than those obtained using conventional approaches. For example, the mechanical properties of a cell can be measured using conventional methods (such as atomic force microscopy) at a throughput of ~10 cells per hour; by contrast, inertial microfluidics has been used to mechanically assess ~65,000 cells per second10. b | Water-in-oil droplet microfluidic technologies are at the forefront of the increase in analytical through put. Thousands of droplets are produced per second, each of which is a precisely defined experimental reaction chamber. Downstream fluidic components carryout serial high-throughput sample processing, which facilitates the analysis of hundreds of millions of samples per day. In one study4, the directed evolution of horseradish peroxidase (HRP) from a mutant yeast library was carried out using droplet microfluidics. The researchers screened 108 individual enzyme reactions in only 10 hours, which is an ~1,000-fold increase in speed and an ~10 million-fold decrease in cost compared with conventional tools. ELISA; enzyme-linked immunosorbent assay.