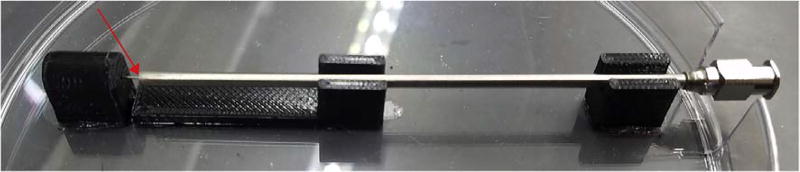

Fig. 6.

Jig for Application of Epoxy to Needles. The three needle jigs provided in the “Design Files Summary” above are here printed in black PLA and used to align the 18-gauge and 250 µm needles for epoxying. The 100 mm-long, 18-gauge needle sits in the right-most and center needle-jig (“18-Gauge Needle Jig_short.STL” and “18-Gauge Needle Jig_extended.STL”). The metal tip of the 250 µm needle, after removal from its plastic luer, is held by the left-most jig in this image. The red arrow indicates where the epoxy is applied to bind the two needles together. In this instance, the jigs were aligned and affixed to a petri-dish using silicone vacuum grease. A rectangular cut was made in the petri dish to make room for the 18-gauge needle.