Table 4.

The use of enzyme-immobilized microreactors for hydrolysis and esterification.

| Immobilization technique | Enzyme | Reaction scheme | Results | Ref. |

|---|---|---|---|---|

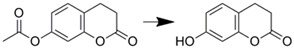

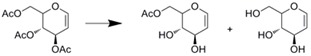

| Surface modification of silica capillary by sol-gel technique/immobilized through amide bond formation using succinate linker | Lipase |  |

1.5 time better yield was obtained compared with batchwise reaction | [45] |

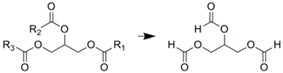

| Entrapment within folded-sheet mesoporous silicas | Lipase |  |

Reaction yield was 10 time higher than batchwise reaction | [63] |

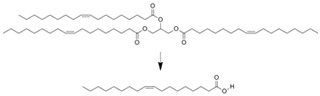

| Covalently immobilized in silica micro structured fiber | Lipase |  |

Almost complete conversion of a vegetable oil to monoacylglycerol | [64] |

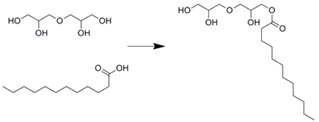

| Entrapment of Novozym-435TM within microchannel | Lipase |  |

Much less of the reactant was required compared with the batchwise test | [65] |

| Ni-NTA agarose bead immobilization | p-Nitrobenzyl esterase |  |

80% yields were obtained along with traces of byproduct | [28] |

| Silica monolith entrapped within microchannels | Protease P |  |

Conversion within microreactor was higher than that of the batchwise reaction at higher flow rates | [33] |

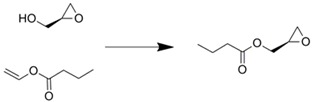

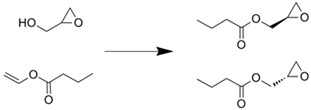

| Silica monolith entrapped within microchannels | Lipase |  |

Optical resolution of products was achieved by connecting commercially available chiral column | [35] |

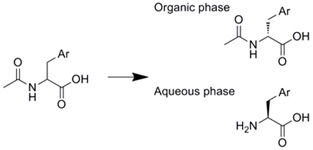

| Membrane formation with paraformaldehyde, glutaraldehyde, and poly-Lys | α-Amino-acylase |  |

Optical resolution of d/l-amino acids were achieved by connecting to micro solvent extractor | [60] |