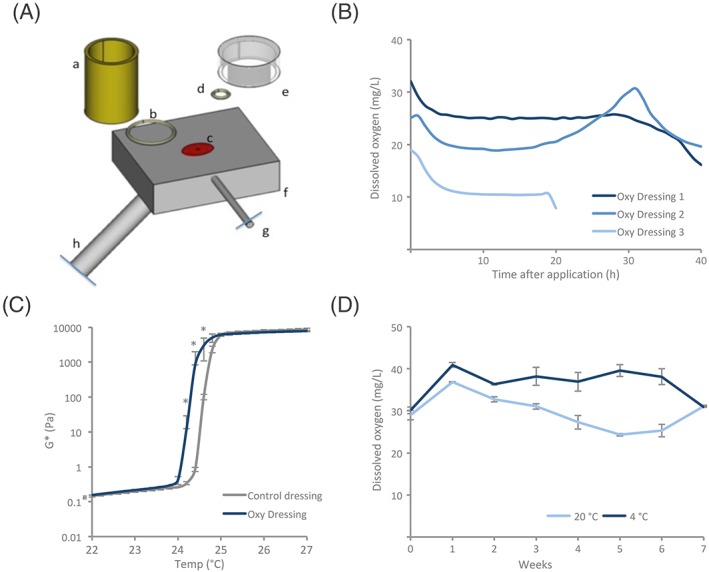

Figure 2.

Characterisation of Oxy Dressing. A, Schematic figure of the oxygen optode setup for continuous determination of DO. The sample reservoir (a), seal (b), optode (c), seal for gels (d), lid for restricted diffusion (e), heating block (f), temperature probe (g), and fiber optic probe (h). B, Stability of DO after application to a 35°C surface was measured with the setup displayed in A (n = 3). Each replicate is shown separately. The average DO concentration in Oxy Dressing replicate 1 and 2 were kept above 22 mg/L for more than 30 hours at 35°C when covered. The third Oxy Dressing replicate had a lower initial DO concentration and dropped to 10 mg/L after approximately 7 hours. C, The influence of viscosity (G*: Shear modulus complex component) on increased temperature for poloxamer 407 formulated in 20 mM acetate buffer with either MilliQ (control dressing) or Oxy Water (Oxy Dressing). Significant gelling was induced at 24°C to 25°C, in both groups. The gelling temperature was significantly lower in the Oxy Dressing in the temperature interval 24.4°C to 24.8°C. Data are presented as average ± SD per 0.2°C (n = 2, * P < 0.05, Mann‐Whitney U test). D, DO was measured in Oxy Dressings after storage at room temperature (20°C) or in fridge (4°C) for 7 weeks. The Oxy Dressing maintained stable DO levels above 30 mg/L when stored at 4°C, and above 20 mg/L when stored at room temperature in capped glass vials for 7 weeks. Data are presented as average ± SD (n = 2 per time point and storage condition)