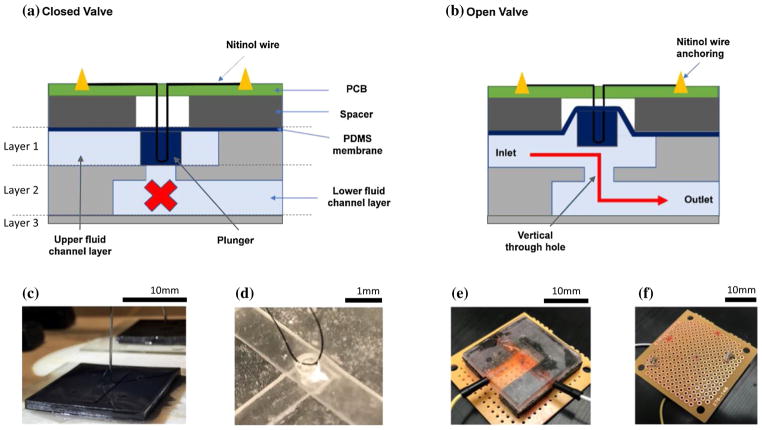

Fig. 1.

Microvalve design and fabrication. a Schematic representation of the microvalve cross section. Under no electrical actuation, the valve is in closed state. The layers 1, 2, 3 delineate the parts of the valve that were manufactured from the same molds. b When the Nitinol wire is actuated electrically, pull force generated on the membrane lifts the plunger upward thereby opening the valve. c Image shows the process of embedding 50-μm surgical suture wire in the uncured polymer matrix. The Nitinol SMA wire was looped around this suture in the final assembly. d Image showing the embedded surgical suture wire in the PDMS membrane layer after the polymer has cured. e The assembled microvalve with copper electrodes embedded in the inlet and the outlet for electrochemical impedance testing. f Nitinol wire anchoring for electrical actuation using low temperature solder