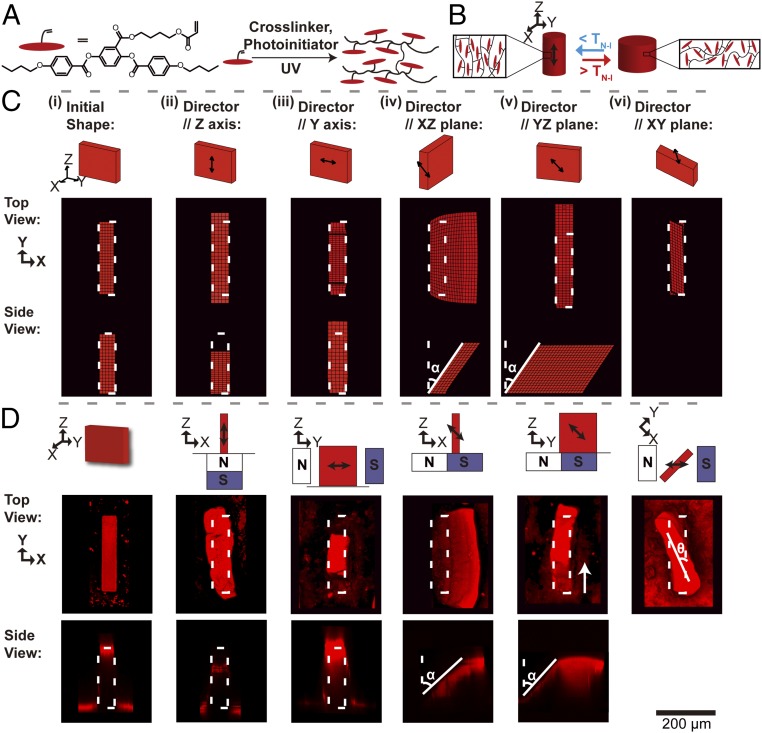

Fig. 1.

Thermal-responsive LCE microplates with different internal molecular configurations. (A) Molecular structure of reactive LC monomer 4″-acryloyloxybutyl 2,5-di(4′-butyloxybenzoyloxy) benzoate and the polymerization process to form a side-on LCE. (B) Schematic illustration of the LCE micropillar that undergoes contraction during the N–I transition when the director is oriented along the structure—the case corresponding to 3D-printed or stretched microstructures. (C) Finite-element simulation results, showing the initial shape (i) and the types of deformation that will originate from the director orientation along the z axis (ii), along the y axis (note the contraction of the top surface in the y direction; iii), in the x–z plane (iv), in the y–z plane (v), and in the x–y plane (vi). White dashed outlines indicate the original shape of the microplate. (D, Top) Schematics showing the relative orientation and position of the plates (shown in red) in designed, 3D magnetic fields that give rise to the director orientations computed in C, ii–vi, respectively. Double-headed black arrows represent the director. (D, Bottom) Fluorescence confocal micrographs of the thermal-responsive deformation of the corresponding synthesized LCE microplates. White dashed outlines indicate the original shape of the LCE microplate. In D, v, the white arrow denotes the vector from the edge of the bottom surface to that of the top surface of the microplate, which has been shifted in the y direction. (C and D) The axes indicate the different planes of projection. α represents the tilting angle and θ illustrates the twisting angle.