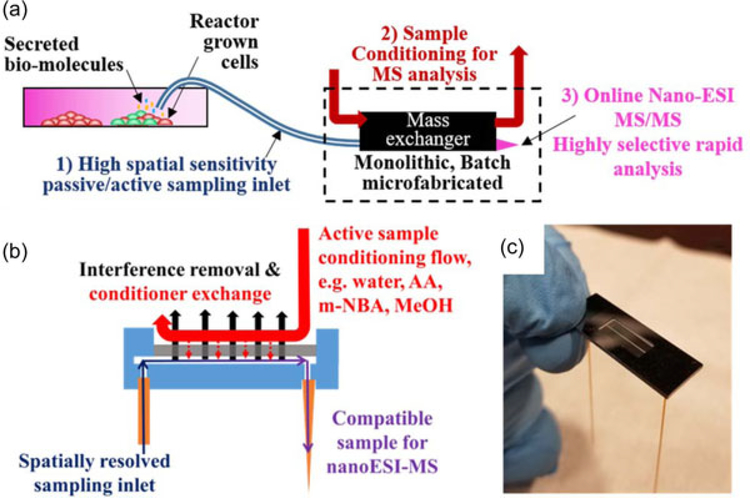

FIGURE 1.

(a) A bioreactor monitoring system should ideally have the ability to continuously sample, either passively (no external pump, capillary filling, flow rates governed by electrospray physics) or actively (forced sampling, flow rates dependent on external pump), from spatially resolved locations within the heterogeneous bioreactor environment for critical quality attributes (CQAs), prepare the sample inline for analysis, and rapidly analyze with high sensitivity, specificity, and quantitation capability, thus providing real-time process control. Nano-ESIMS/MS is a promising analysis approach for untargeted CQA discovery and bioreactor monitoring. (b) Cross-sectional view of the dynamic mass spectrometry probe (DMSP), which enables direct sampling from a bioreactor via a fused silica inlet capillary, sample conditioning and direct online nano-ESI-MS analysis. Conditioning in the mass exchanger includes removal of salt and any other small interfering chemicals, and solvent exchange. Introduction of proton donating chemicals such as acetic acid (AA), protein denaturing solvents such as methanol (MeOH) and supercharging solutes such as 3-nitrobenzyl alcohol (m-NBA) in the mass exchanger can improve sensitivity. (c) Microfabricated monolithic DMSP without conditioning flow package to allow visualization of the sample channel through the semi-transparent nanoporous alumina mass exchange membrane. ESI-MS: electrospray ionization mass spectrometry [Color figure can be viewed at wileyonlinelibrary.com]