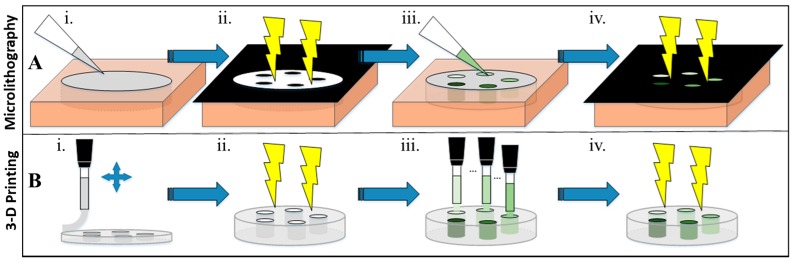

Figure 1.

Scheme of microlithographically produced and 3-D printed hybrid hydrogel structures. (A) Microlithography: (i) 50 µL of hydrogel cocktail was pipetted into a silicone isolator and then (ii) covered with a mask and crosslinked for 5 min under UV. (iii) The mask was removed, the non-crosslinked cocktail was washed off, and electroconductive hydrogels were pipetted into the wells. (iv) The wells were then covered in a reverse mask and crosslinked for 5 min under UV. (B) 3-D Printing: (i) A syringe loaded with a hydrogel cocktail was used to extrusion print the outer part of the hydrogel (layer-by-layer) with a (ii) 30 s UV crosslinking done between each layer. (iii) The five wells were then printed with the electroconductive cocktails and subsequently (iv) UV crosslinked for 5 min.