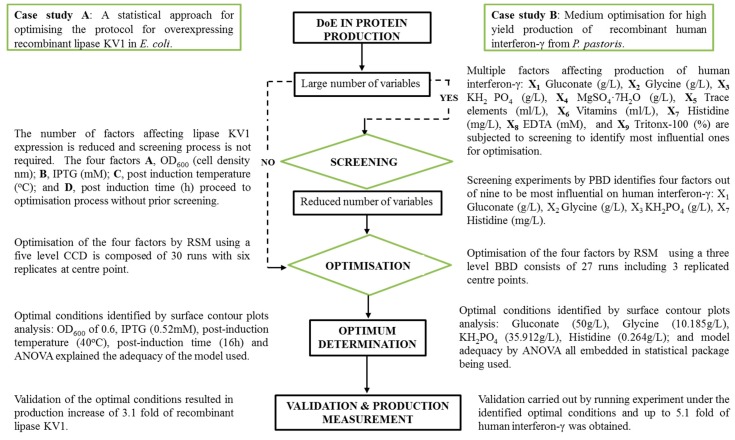

Figure 1.

A typical DoE workflow in protein production. Case study A illustrates the optimization of recombinant lipase KV1 expression in E. coli [84] where a screening process was not required since the number of factors affecting this enzyme is not large (four factors). The four factors (A, B, C, D), therefore, underwent optimisation by Central Composite Design (CCD) under Response Surface Methodology (RSM) which resulted in a yield increase in protein expression of 3.1-fold. Case study B describes the optimisation process for high yield production of recombinant human interferon-γ [85]. In this case, the number of factors involved is large (nine factors) and they were subjected to a screening process before optimisation. Four factors (X1, X2, X3, X7) out of nine were identified by Plackett-Burman Design (PBD) based screening to be the most influential and subsequently used for further optimisation. A Box-Benkhn Design (BBD) also under RSM was selected to optimize the screened factors and increased the production of human interferon-γ up to 5.1 fold. Further details of these two case studies can be found in the references provided and similar cases are found in Tables 4 and 7.