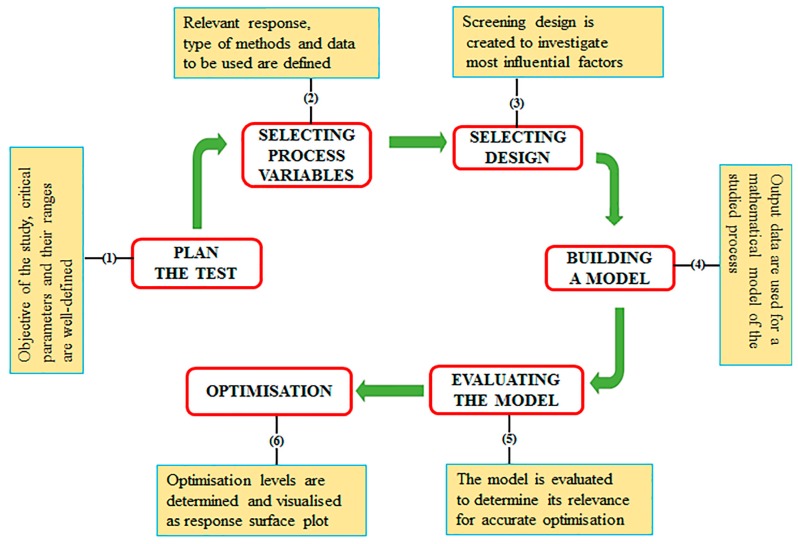

Figure 3.

A typical DoE workflow for the optimisation of recombinant protein production. The figure describes the main steps involved in the experimental design when both screening and optimisation designs are used. (1) The objectives of the study are defined including the selection of factors, levels and responses. (2) Process variables and expected responses are identified; the process variable levels (for a 2 level study) are set as high (+1), low (−1), (on occasion a 0 point is included). (3) The experimental screening design is selected based on the objectives of the study and the number of factors involved. (4) A mathematical model is built with certain conditions to meet the desired objectives (e.g., measurement of all the desired responses, process stability and accurate approximation by polynomial models). (5) The response data are analysed and visualised using plots for ease of data interpretation. At this stage, a reduced number of factors (i.e., the most influential) are retained for the subsequent optimisation phase. (6) Further optimisation can be carried out (via an optimisation DoE design).