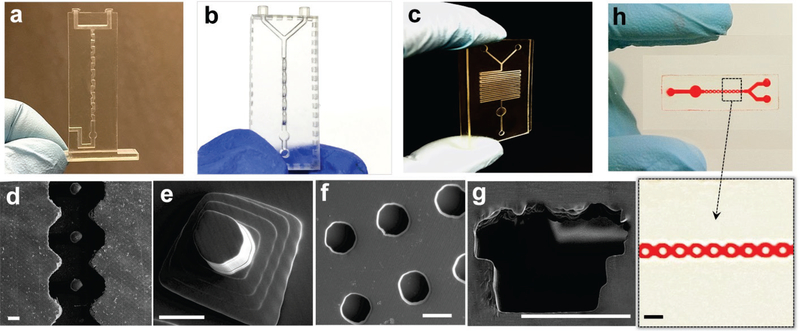

Figure 3.

Characterization of 3D printing for fabricating microfluidic mixers: (a) SAR microfluidic mixer, (b) 3D ring-shaped micromixer, (c) and serpentine micromixer. Channel diameter is ~500 μm. SEM imaging was used to characterize variable 3D-printed microstructures: (d) posts in curved microfluidic channel, (e) pyramid post arrays, (f) microwells, and (g) a D-shaped hollow microchannel. Scale bar: 200 μm. (h) The bonded layer of a 3D-printed open channel with a glass slide.