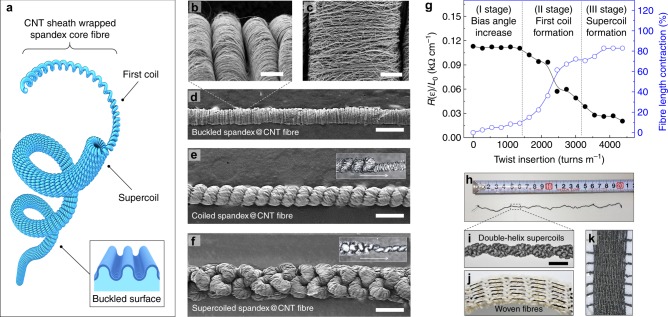

Fig. 1.

Schematic illustration and morphological information of supercoiled fibres. a Schematic illustration of highly twisted spandex@carbon nanotube (CNT) fibre, consisting of first-coils and supercoils. Inset shows a schematic of microscale buckled surface. Scanning electron microscopy (SEM) images for b microscopic scaled buckles formed on the surface of spandex@CNT fibre relaxed from pre-strain (scale bar = 15 μm), and c its magnification showing uniaxially aligned CNT bundles (scale bar = 5 μm). SEM images for d noncoiled, e first coiled, and f supercoiled spandex@CNT fibres, showing subsequent structure transformations as the number of twists increases (scale bars for d, e, and f are 200 μm). Inset images from e and f show fibre transformations from noncoiled fibre into first coil, and from first coil into supercoil, respectively. The arrows indicate the propagation direction of coil formation. g Measured length-normalised resistance changes and fibre length contraction versus number of inserted twists until full supercoiling (R(ε) is the resistance of fibre at the stretched state and L0 is the length of fibre at the initial state). Photograph of h free-standing state, double-helix structured, supercoiled fibre, and optical images of i its magnification (scale bar = 1 mm), j 3.5-cm-long, six-woven supercoiled spandex@CNT fibres into a commercial mock rib-structured textile, and k 20 mm-long, 7 mm-wide supercoil textile consisting of 27 spandex@CNT fibres