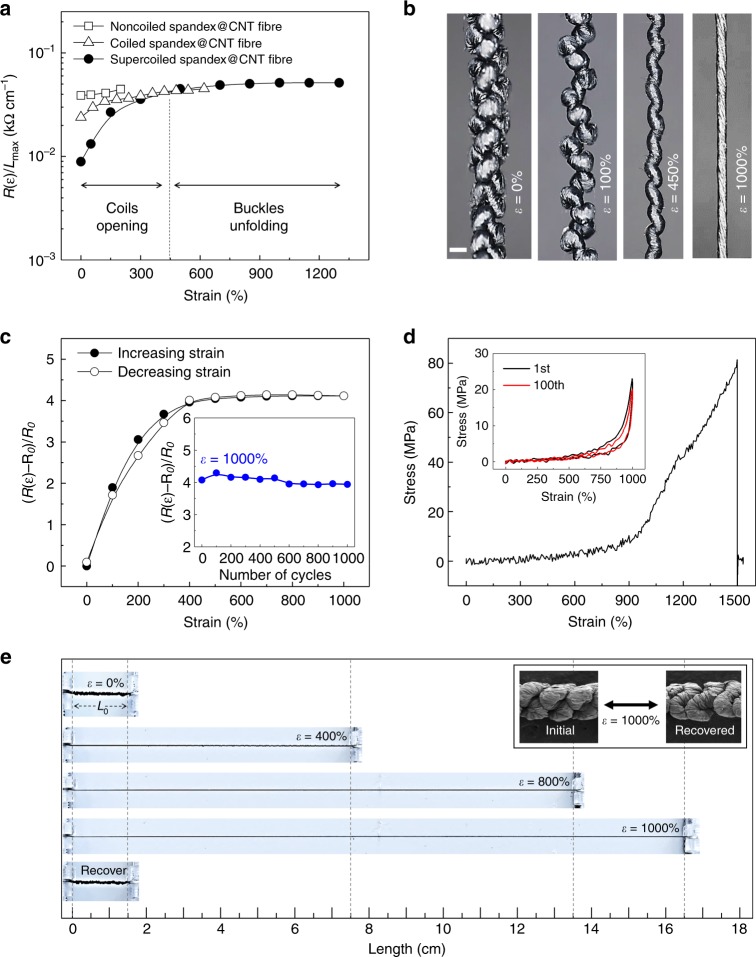

Fig. 3.

The strain dependence of electrical and mechanical properties. a Length-normalised resistance versus strain for noncoiled (open squares), coiled (open triangles), and supercoiled fibres (black circles). R(ε) is the resistance of fibre at the stretched state and Lmax is the length of fibre at the fully stretched state. b Optical images for supercoil fibre showing progressive coil opening during application of 0, 100, 450, and 1000% strain (scale bars = 200 µm). c Resistance change ratio for a supercoil fibre versus strain for a 1000% strain loading-unloading (R0 is the resistance of fibre at the initial state). Inset shows resistance change versus cycle number of 1000% strain applications. d Engineering stress–strain curve for 150-μm-diameter supercoil fibre. Inset shows stress–strain curves compared before (black line) and after (red line) 100th for 1000% strain loading-unloading application. e Photographs showing the supercoiled fibre mounted on digital Vernier calipers (the initial supercoiled fibre length was 1.5 cm). The fibre is subsequently stretched to strains of 400, 800, 1000% (16.5 cm), and recovered to the initial state. Scanning electron microscopy (SEM) images presented in the inset show (left) pristine macroscopic scale supercoil structures and (right) their relaxation after 1000% strain application