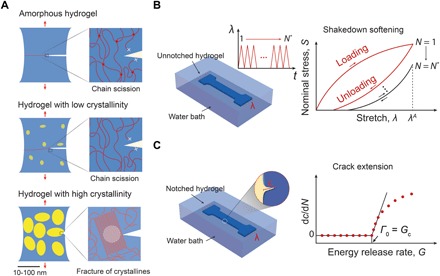

Fig. 1. Design principle for anti-fatigue-fracture hydrogels.

(A) Illustration of fatigue crack propagation in an amorphous hydrogel and in hydrogels with low and high crystallinities under cyclic loads. The yellow areas represent crystalline domains, and the blue areas denote amorphous domains. In the amorphous hydrogel and the hydrogel with low crystallinity, the fatigue threshold can be attributed to the energy required to fracture a single layer of polymer chains per unit area. In the hydrogel with high crystallinity, the fatigue crack propagation requires fracture of crystalline domains. (B) Illustration of measuring nominal stress S versus stretch λ curves over N cycles of the applied stretch λA. The stress-stretch curve reaches steady state as N reaches a critical value N*. (C) Illustration of measuring crack extension per cycle dc/dN versus energy release rate G curves. By linearly extrapolating the curve to intercept with the abscissa, we can approximately obtain the critical energy release rate Gc, below which the fatigue crack will not propagate under infinite cycles of loads. By definition, the fatigue threshold Γ0 is equal to the critical energy release rate Gc.