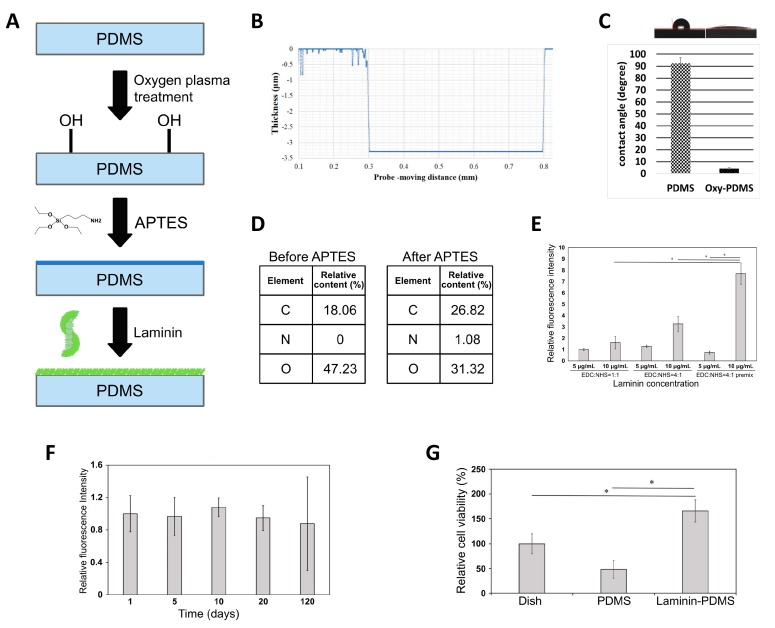

Figure 1.

Production and characterization of laminin-modified PDMS film. (A) Schematic representation of the manufacturing process of laminin-coated PDMS, consisting of stages of hydrophilization with oxygen plasma, silanization with APTES, and crosslinking laminin. (B) Measurement of the thickness of the PDMS membrane by surface profiler. (C) Water contact angle measurement before (left) and after (right) oxygen plasma treatment. (D) X-ray photoelectron spectroscopy analysis, showing increased carbon and nitrogen elements in PDMS due to APTES grafting. (E) Optimization of laminin concentration and crosslinking agent ratio (EDC:NHS) used for laminin crosslinking. (F) Stability of laminin crosslinked to PDMS membrane in a course of 120 days measured by immunofluorescence assay. (G) Cell viability assay performed on ARPE-19 cells grown on laminin-modified PDMS as compared to uncoated laminin and culture dish plastic. The values in (E–G) are the means from three independent measurements with SD error bars, * indicates statistically significant difference (ANOVA, p < 0.05).