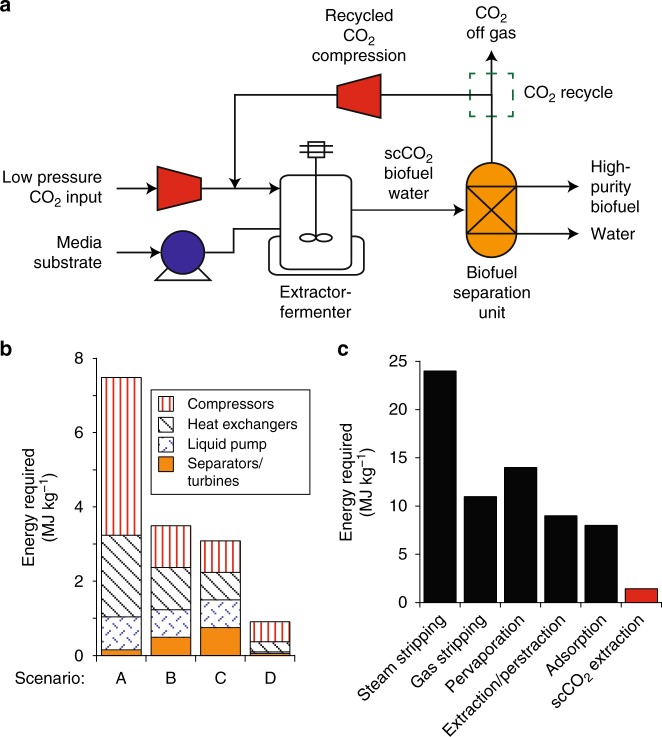

Fig. 5.

Isobutanol energy recovery requirements for integrated fermentation-extraction under scCO2. a Simplified process schematic of the envisioned scCO2 bioprocess used to develop an Aspen Plus model, including compression of CO2 to scCO2, fermentation/extraction, de-pressurization/biofuel recovery, and CO2 recycle. Further detail is provided in Supplementary Fig. 15a. b Energy requirement for isobutanol recovery as MJ kg−1 for several scenarios. Separate fermentation and scCO2 recovery processes represent the base case (scenario A). Scenario B is coupled fermentation and extraction without use of partial extraction stream de-pressurization or scCO2 recycle. Scenario C de-pressurizes the extraction stream to 6.5 MPa to induce formation of an isobutanol-rich stream, which permits recycling of compressed CO2, set at 50% (by mass). Scenario D again de-pressurizes to 6.5 MPa and recycles the maximum possible amount of CO2 (87%) that results in no accumulation of CO2 in the system. Values for b can be found in Supplementary Table 6. c Comparison of the energy requirements for isobutanol production found for the scCO2 process relative to published literature values for alternative in situ recovery methods28. The scCO2 extraction energy requirement in c is for coupled fermentation and extraction with partial de-pressurization and full recycle (i.e., Scenario D in b). Source data are provided as a Source Data file