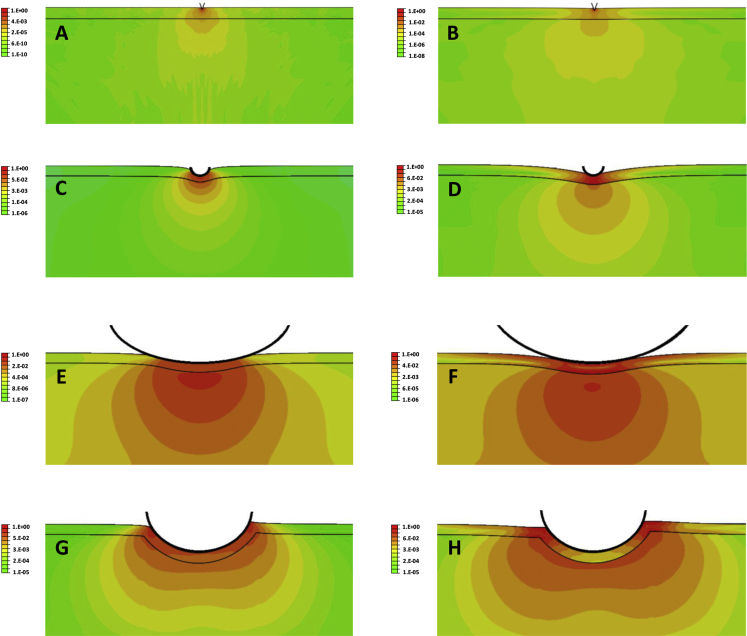

Figure 6.

Strain-energy distribution (log scale) for indentation into a cell of a sharp AFM tip (A and B), a 0.8 μm diameter rounded AFM tip (C and D), a 10 μm diameter rounded AFM tip (E and F), and a 4.5 μm OMTC bead (G and H). The indentation is smaller in cases (A) and (B) (80 nm) because of numerical limitations, as discussed in the Materials and Methods, than for the other AFM tips (400 nm). The OMTC bead is embedded 25% of its diameter into the cell and twisted by a torque of 60 Pa applied in a counterclockwise fashion. (A), (C), (E), and (G) are for cases with Ecortex = Eintracellular; (B), (D), (F), and (H) are for Ecortex = 50 × Eintracellular. The cortex in each panel is the narrow region between the two horizontal black lines and has a thickness of 400 nm before indentation. The strain-energy distribution in each panel is normalized to the maximal strain energy in that panel, and a log scale is used. Cell thickness is 5 μm.