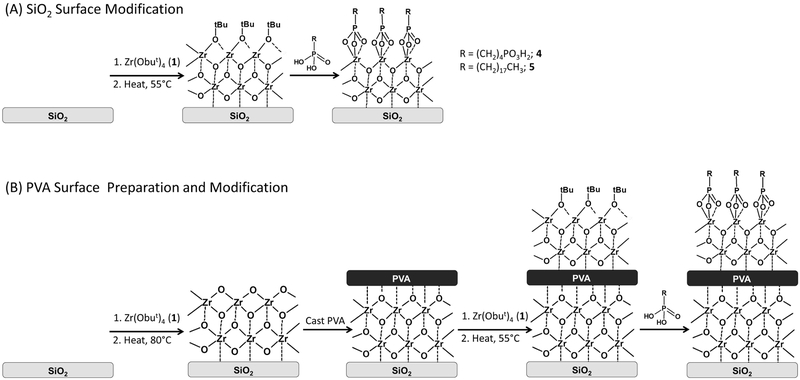

Figure 1.

SAMP surface modification scheme. (A) SiO2 surface modification: clean SiO2 is exposed to 1 vapor and then gently heated to 55° C to form a mixed Zr oxide/alkoxide layer (2). The 2-terminated SiO2 is then immersed in an ethanol solution of a phosphonic acid to yield SAMP-terminated SiO2. (B) PVA film fabrication and surface medication: clean SiO2 is exposed to 1 vapor and then heated to 80° C to form a ZrO2 layer (3). The 3-terminated SiO2 is spin-cast with PVA from a formic acid solution to yield a PVA thin film supported on a 3-terminated SiO2 substrate. The PVA film is exposed to 1 vapor and gently heated to 55° C to form a mixed Zr oxide/alkoxide layer, and is then immersed in an ethanol solution of a phosphonic acid to yield a SAMP-terminated PVA film surface. Note: this schematic is not meant to imply any particular stoichiometry.