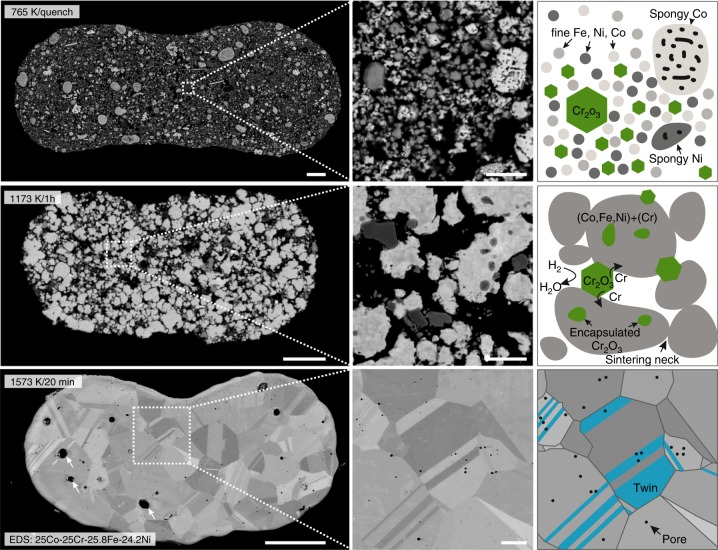

Fig. 3.

Microstructural evolution of 3D extrusion printed CoCrFeNi HEA filaments. top) Cross-section of a 3D extruded filament heated to 765 K in H2 and quenched in Ar. A fine structure of metallic Fe, Ni and Co with inter-dispersed Cr2O3 is observed (right). center) Filament sintered at 1173 K for 1 h showing sintering of the (Co, Fe, Ni, Cr)-matrix leading to partial encapsulation of Cr2O3 (right). Smaller Cr2O3 particles were reduced to Cr and dissolved (Supplementary Figure 3). bottom) CoCrFeNi HEA filament sintered at 1573 K for 20 min showing a coarsened grain structure (grain size of 5 to 25 µm) with annealing twins, swelling voids (~2–5 µm, arrows) and sub-micrometer pores. Filaments are flattened due to printing on a substrate and gravitational sagging. Scale bars are 25 µm for low magnification (left) and 3 µm for high magnification (center) micrographs