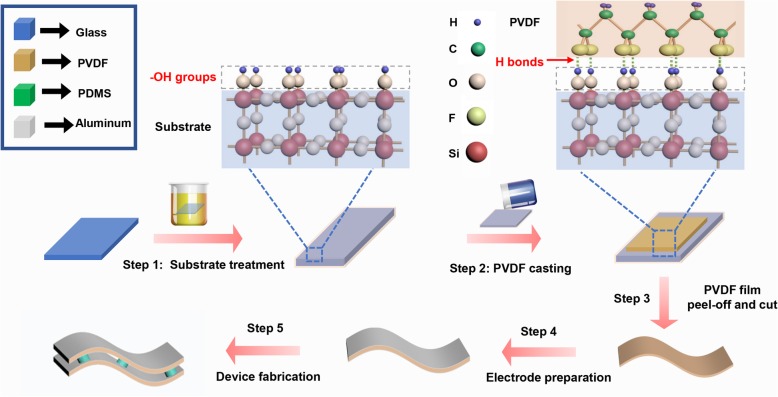

Fig. 1.

Illustration of PVDF film and device preparation process. Step 1, the glass substrate was soaked in piranha solution for 2–8 h. Step 2, well-stirred PVDF solution was cast on the substrate and dried at 80 °C for 10 h. Step 3, the PVDF film was peeled off from the substrate, and the edge was cut off to remove edge effect. Step 4, aluminum was evaporated onto both sides of the film as electrodes. Step 5, the bilayer device was fabricated by using PDMS pillars supported between the two layers as separators. Also indicated were schematics of the hydroxyl groups bonded on the surface of the glass substrate after treatment, hydrogen bonds formation after PVDF casting and orderly arrangement of the “ultra-thin layer” at the bottom of PVDF film