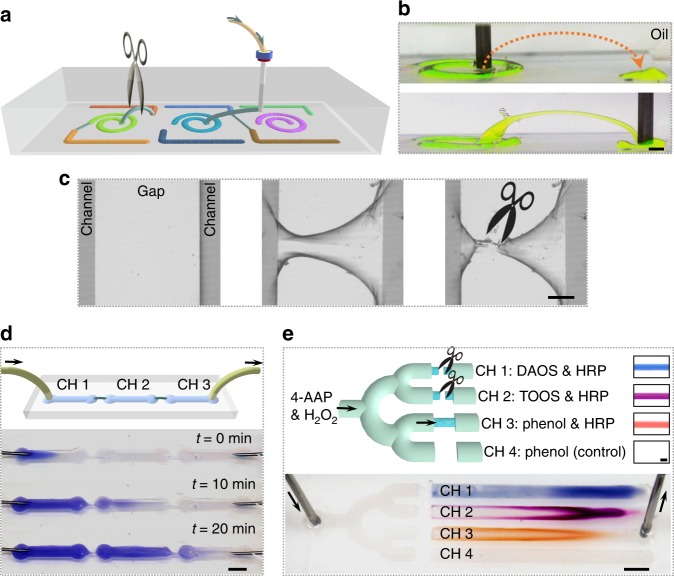

Fig. 4.

Reconfigurable 3D all-liquid microreactors with logical optical outputs. a Schematic of fabricating 3D microchannels stabilized by nanoclay-surfactant interfacial assembly to connect the separated microchannels by printing of water in oil. Disconnecting these microchannels is also possible by cutting these “bridges” off. b Adjacent channels on a patterned substrate connected by a 3D printed overpass. Na-fluorescein (0.1 mg mL−1) has been added to the clay dispersion to clarify features of the constructs. Scale bar: 2 mm. c Fabrication of a 3D bridge linking separate channels (middle panel) and clipping the bridge (right panel). Scale bar: 500 µm. d Time-lapse showing a dyed solution pumped through liquid channels CH 1, CH 2, and CH 3, which are connected by printed 3D bridges. Scale bar: 5 mm. e Chemical transformations yielding chromogenically distinct products are conducted consecutively by forming and then breaking bridges between the inlet and various patterned channels containing different reagents. The bridges are built using liquid-in-liquid 3D printing to yield a “turn-on” state, and mechanically broken to yield a “turn-off”. Inset photographs on top show the solutions collected in capillaries after carrying out these chromogenic reactions in vials. DAOS: N-ethyl-N-(2-hydroxy-3-sulfopropyl)-3,5-dimethoxyaniline, sodium salt. TOOS: N-ethyl-N-(2-hydroxy-3-sulfopropyl)-3-methylaniline, sodium salt. Scale bars: 1 mm (top) and 5 mm (bottom)