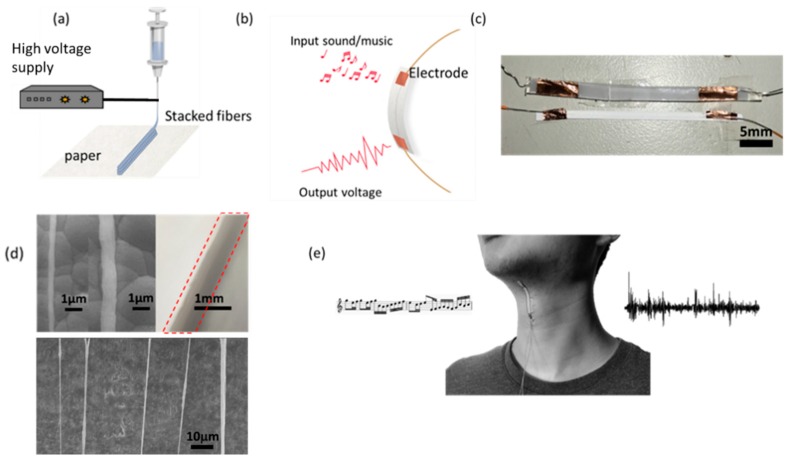

Figure 1.

Schematic illustration of the fabrication process and the morphology of ISSE. (a) One-step fabrication process of ISSE. Nano/micro PVDF fibers were directly deposited on the printing paper by using near-field electrospinning (NFES). (b) ISSE has the ability of detecting sound in one device. (c) The optical photo of sound sensing element. (d) The morphology of two nano/micro fibers (top) and multiple aligned fibers (bottom) as produced at 1.5 kV. Due to the spinnability of NFES, the fiber diameters were typically in the range of 500 nm to 3 μm. (e) The artificial throat can detect the movement of throat and music sound, respectively. The controllability of the stacked ~100 layer electrospun PVDF fibers wall structure is demonstrated by a variety of NFES processing conditions such as x–y translational motion stage speed, PVDF weight-volume, and spinner-to-collector distance.