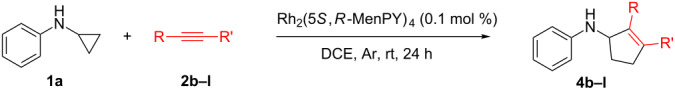

Table 3.

Substrate scope of alkyne derivativesa.

| |||||

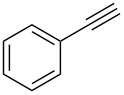

| Entry | Substrate | Product | Yieldb(%) | ||

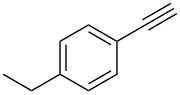

| 1 |  |

2b | N.D. | 4b | N.R. |

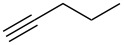

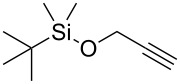

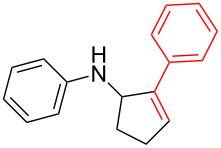

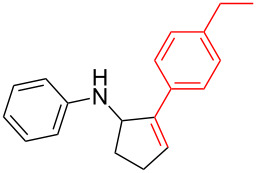

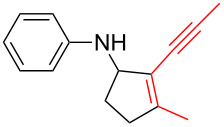

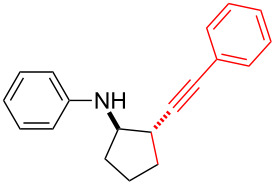

| 2 |  |

2c |  |

4c | <10 |

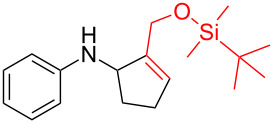

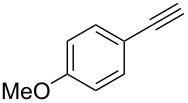

| 3 |  |

2d |  |

4d | 65 |

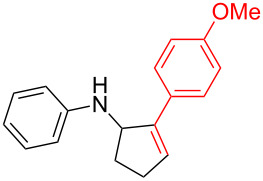

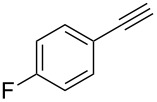

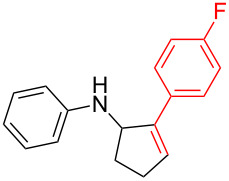

| 4 |  |

2e |  |

4e | 64 |

| 5 |  |

2f |  |

4f | 65 |

| 6 |  |

2g |  |

4g | 64 |

| 7 |  |

2h |  |

4h | 31 |

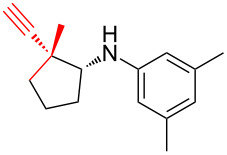

| 8c |  |

2i |  |

4id,e | 45 (17:83)f |

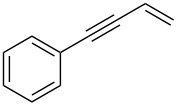

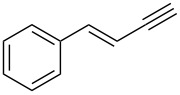

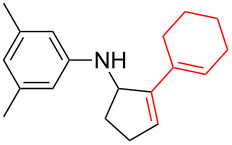

| 9 |  |

2j |

, ,

|

4j | 41 (30:70)f |

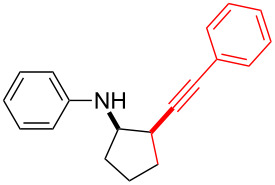

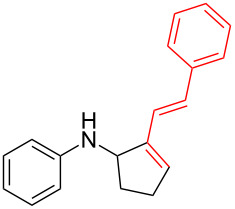

| 10 |  |

2k |  |

4k | 44 |

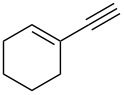

| 11c |  |

2l |  |

4ld | 40 |

aReaction conditions: 1a (1 mmol, 0.2 M in degassed solvent), 2b–l (5 mmol), catalyst (0.1 mol %) at room temperature for 24 h unless otherwise noted. bIsolated yield. cN-Arylaminocyclopropane 1d was used instead of 1a. dMajor isomer shown. eIsomer ratio 89:11. fDiastereoisomeric ratios (cis/trans) were determined by 1H NMR spectroscopy of the crude products.