Fig. 4.

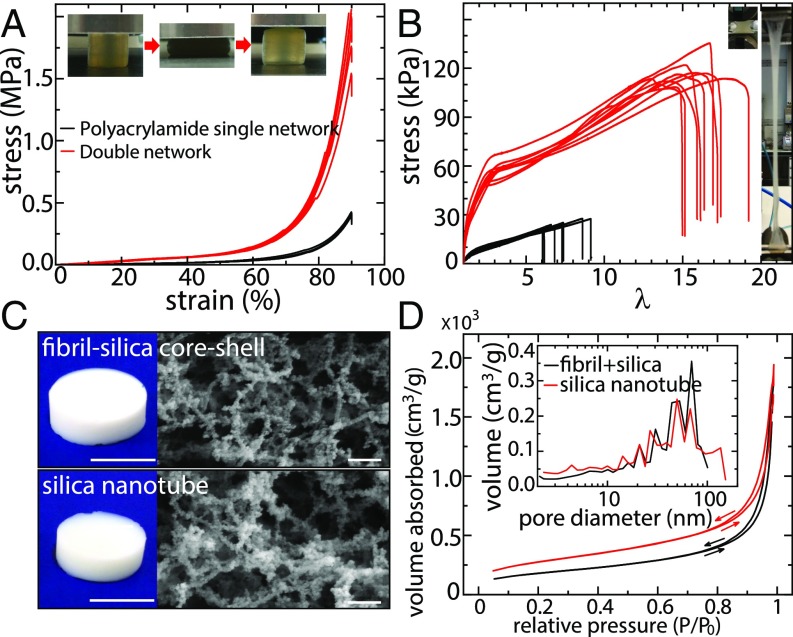

DN hydrogels and aerogels. (A) Compressive stress–strain curves of the polyacrylamide SN and the fibril/polyacrylamide DN hydrogels with certain repeated experiments. Insert displays that the DN hydrogel could recover even with a compression of 50% initial height. (B) Tensile stress–stretch curves of the polyacrylamide SN and the fibril/polyacrylamide DN hydrogels with certain repeated experiments. Insert shows that the DN hydrogel could be elongated to 17 times its initial length. (C) Photos and SEM images of the fibril–silica core–shell aerogel (Upper) and silica nanotube aerogel (Lower). The silica nanotube aerogel was generated by calcining the fibril–silica aerogel at 700 °C for 2 h. (Scales bars in photos and SEM images: 1 cm and 200 nm, respectively.) (D) Nitrogen gas absorption–desorption curves of the fibril–silica aerogel and silica nanotube aerogel, with the pore size distributions in Insert, derived from the nitrogen desorption.