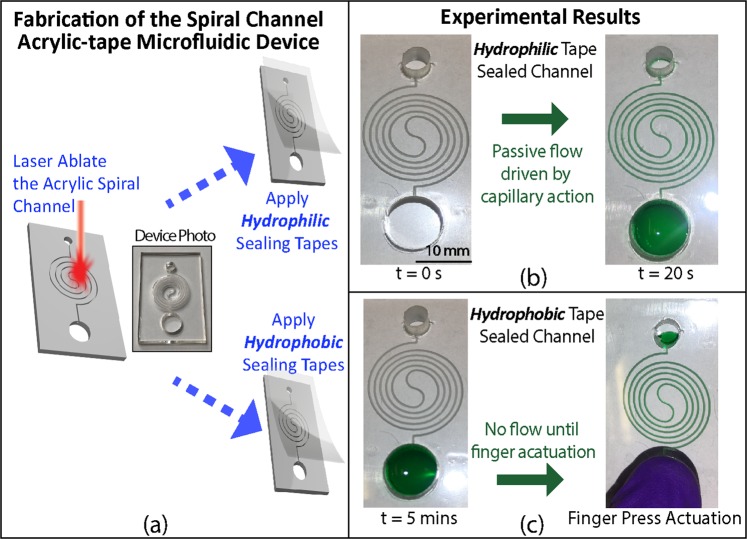

Figure 4.

(a) Fabrication and assembly of the spiral channel acrylic microfluidic devices with reconfigurable flow actuation mechanisms. A spiral microfluidic channel is laser ablated onto an acrylic board. Either a hydrophilic or a hydrophobic tape is applied to seal the channel. (b) Automatic pump-free flow actuation with the spiral acrylic microfluidic channel sealed by a hydrophilic tape. Water with green dye was dropped into the inlet at t = 0. The whole channel was automatically filled due to the passive capillary action at t = 20 s. (c) Finger-press flow actuation with the same spiral channel sealed by a hydrophobic tape. Water with green dye was dropped into the inlet at t = 0 and could not flow into the channel after 5 minutes because of the tape hydrophobicity, until actuated by a finger press on the inlet. The scale bar is 10 mm. The results in this figure were obtained with acrylic channels fabricated using the vector ablation method shown in Fig. 1 and can be repeated with channels made by raster ablation (data not shown).