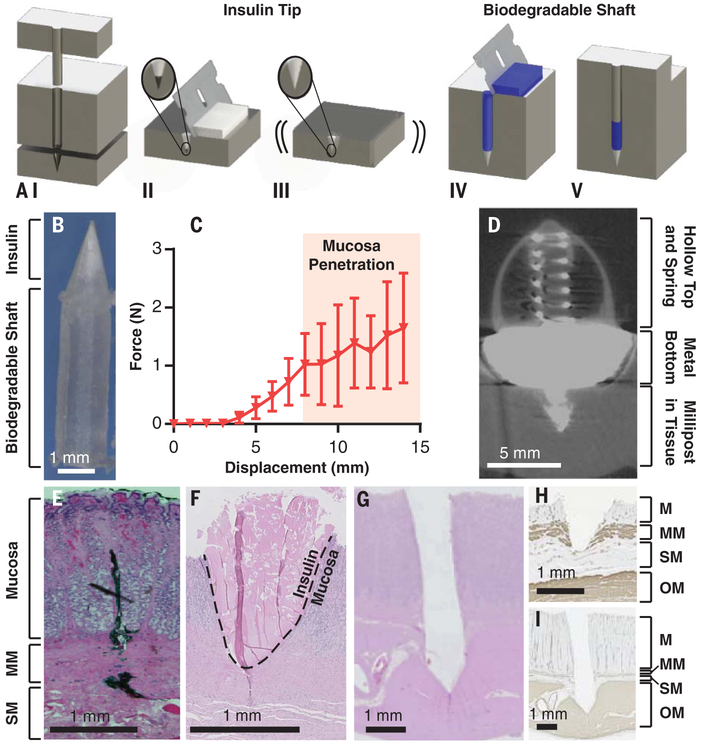

Fig. 3. Millipost fabrication and insertion-force characterization.

(A) (I) Millipost stainless steel mold. (II) API mixture screen-printed into tip section. (III) Vibrations ensure powder fills cavity. (IV) Top section filled with biodegradable polymer. (V) Material compressed at 550 MPa. (B) 7-mm-long insulin millipost. (C) In vivo insertion force profile of insulin milliposts propelled at 0.2 mm/s in swine stomach (n = 2 stomachs, n = 8 insertions). Error bars indicate SD. (D) Micro-CT imaging of SOMA delivering a barium sulfate millipost into swine stomach tissue. Bottom is larger to ensure millipost stability during imaging. (E) Swine stomach hematoxylin and eosin-stained histology of dye injected by Carr-Locke needle in vivo to demonstrate penetration depth, (F) insulin millipost injected via a 5-N spring in the SOMA in situ, and (G) steel millipost inserted with a 9-N spring ex vivo. (H and I) Immunohistochemistry histology stained against α-smooth muscle actin of events in (F) and (G). M, mucosa; MM, muscularis mucosa; SM, submucosa; OM, outer muscularis.