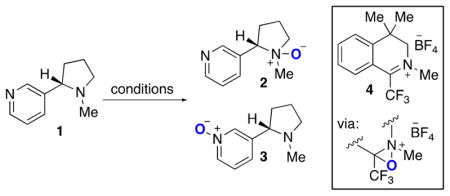

Table 1.

Optimization of the Reaction Conditionsa

| ||||

|---|---|---|---|---|

| entry | substrate | conditionsa | ratio of 1:2:3b | yield of 3 (%)c |

| 1 | 1·HBF4 | m-CPBA, CH2Cl2, rt | 1:5:0 | — |

| 2 | 1·HBF4 | H2O2, AcOH, 80 °C | 0:1:0 | — |

| 3 | 1·HBF4 | DMDO, CH2Cl2, rt | 11:0:1 | — |

| 4 | 1·HBF4 | H2O2, 4 (20 mol %) | 1:0:5 | 77% |

| 5 | 1 | HBF4·OEt2, H2O2, 4 (20 mol %) | 1:0:4 | 77% |

| 6 | 1 | HBF4·OEt2, H2O2 | 1:0:0 | — |

| 7 | 1 | HBF4·OEt2, m-CPBA | 2:5:0 | — |

| 8 | 1 | H2O2, 4 (20 mol %) | 0:1:0 | — |

| 9 | 1 | H2SO4, H2O2, 4 (20 mol %) | — | 66% |

| 10 | 1 | HBF4·OEt2, DMDO | — | 15% |

One equivalent of oxidant was used for entries 1, 3, 7, and 10. Two equivalents were used for entries 4–6, 8, and 9. Four equivalents were used for entry 2. For entries 4–10, a 5:1 mixture of CH2Cl2:HFIP was used as the solvent, and the reactions were run at room temperature.

Ratios determined by integration of HPLC chromatograms.

Isolated yield.