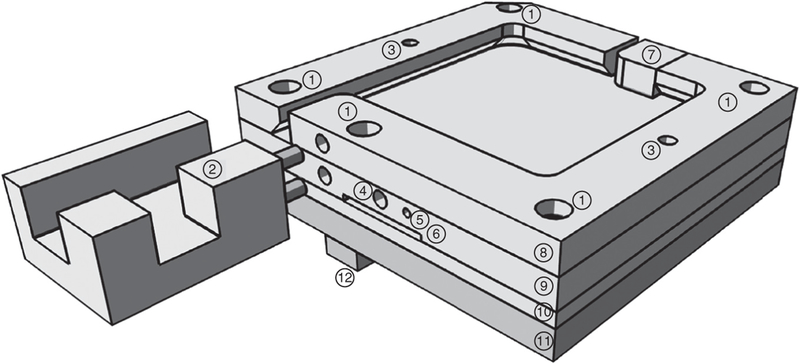

Figure 1|.

Structure of the in-house-manufactured column heater. Labeled rendering shows the column oven without a lid. (1) Holes for 4–40 ×¾-inch screws to attach the four layers to one another. (2) Polycarbonate micro-tee retainer. (3) Holes to accept pins from lids (not shown). (4) Hole for resistance thermometer. (5) Hole for grounding wire. (6) Slot for foil heater connections. (7) Spring-loaded column tip retainer. (8) Undercut top layer. (9) Layer containing thermometer, heater (against bottom), and grounding wire. (10) Aluminum layer between heater and polycarbonate base plate. (11) Polycarbonate base plate. (12) Polycarbonate attachment to the nanospray ion (NSI) source.