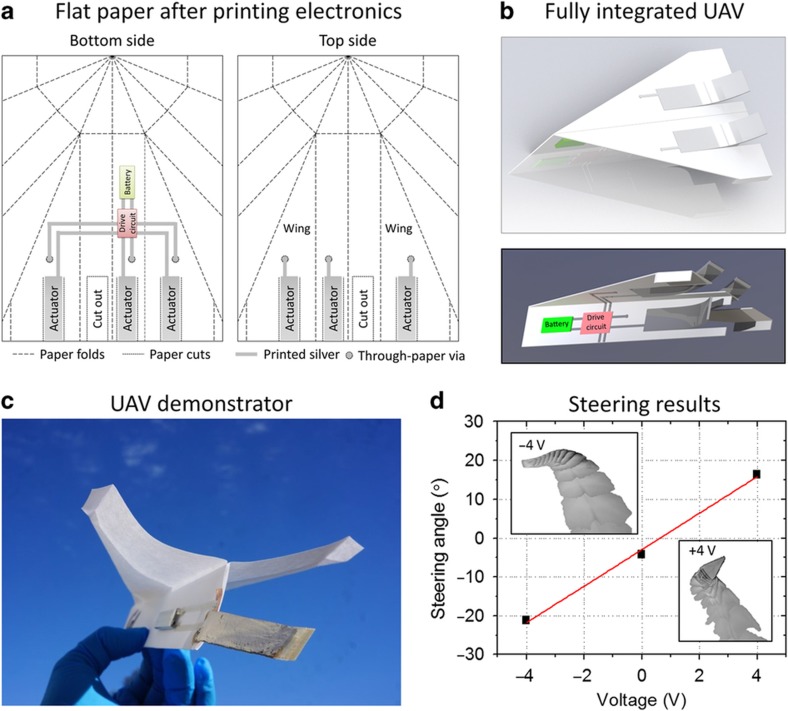

Figure 2.

Vision of UAV integration with electronics for a fully printed UAV. (a) All UAV components could potentially be printed directly onto or into a flat paper substrate using roll-to-roll processes, including actuators, power sources, drive circuits, and interconnects. Printing must be performed on both sides of the paper substrate to drive both the actuator electrodes and other potential payload circuits. Connections can be made through the thickness of the paper using laser-cut through-paper vias filled with silver ink. (b) The final three-dimensional UAV structure would be created by folding the initially flat paper substrate. Actuators would be released by laser cutting the surrounding paper and would bend when a voltage is applied. The locations of these folds and cuts are indicated in a. (c) Paper UAV demonstrator with a separately fabricated and attached single paper-based rudder for horizontal steering and a lightweight battery connected by stencil-printed silver interconnects. (d) The horizontal steering angle of the demonstrator UAV depends on the applied actuator voltage, as expected, thus allowing steering to the left and right, that is, control of the yaw angle. Insets show the extracted UAV images from successive video frames overlaid on top of each other as the UAV is flying away from the camera. One can clearly see the UAV turning left and right depending on the polarity of the applied voltage (negative and positive, respectively). UAV, unmanned aerial vehicle.