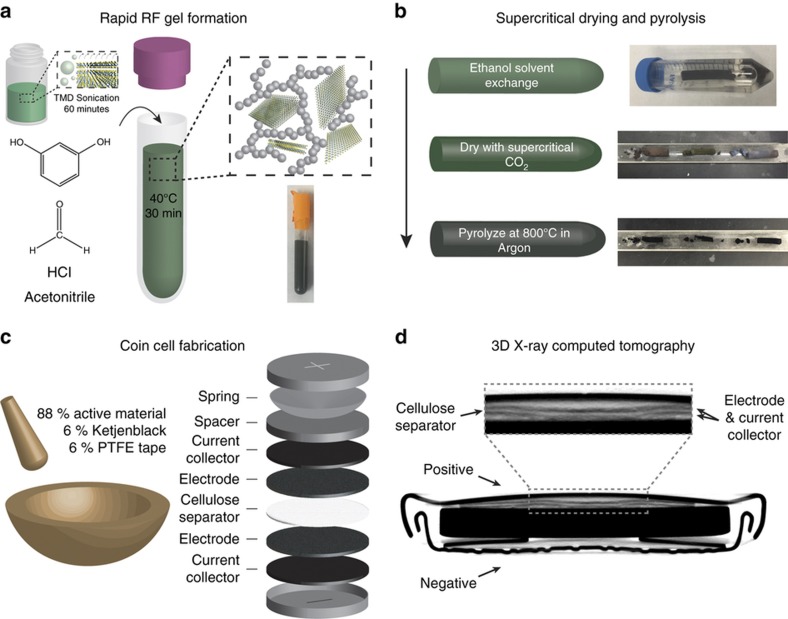

Figure 1.

Outline of the nanomanufacturing process for composite TMD carbon aerogels. Initially, sonication-driven cavitation (a) drives TMD sheets apart and enhances dispersion within acetonitrile. Resorcinol and formaldehyde are added to this solution, which causes rapid sol-gel formation, catalyzed by hydrochloric acid. This gel is washed with ethanol to remove any unreacted species and dried with supercritical CO2 (b) to displace the solvent without destroying its pore structure before being pyrolyzed in argon. Finally, we process this material into a supercapacitor by grinding it with carbon black additive (Ketjenblack) and PTFE tape, rolling and punching it into electrodes that are assembled into a symmetric coin cell, and adding the resulting electrode to a full coin cell, using a cellulose separator, illustrated in (c). A three-dimensional X-ray computed tomography image of a coin cell after 10 000 charge–discharge cycles (d).