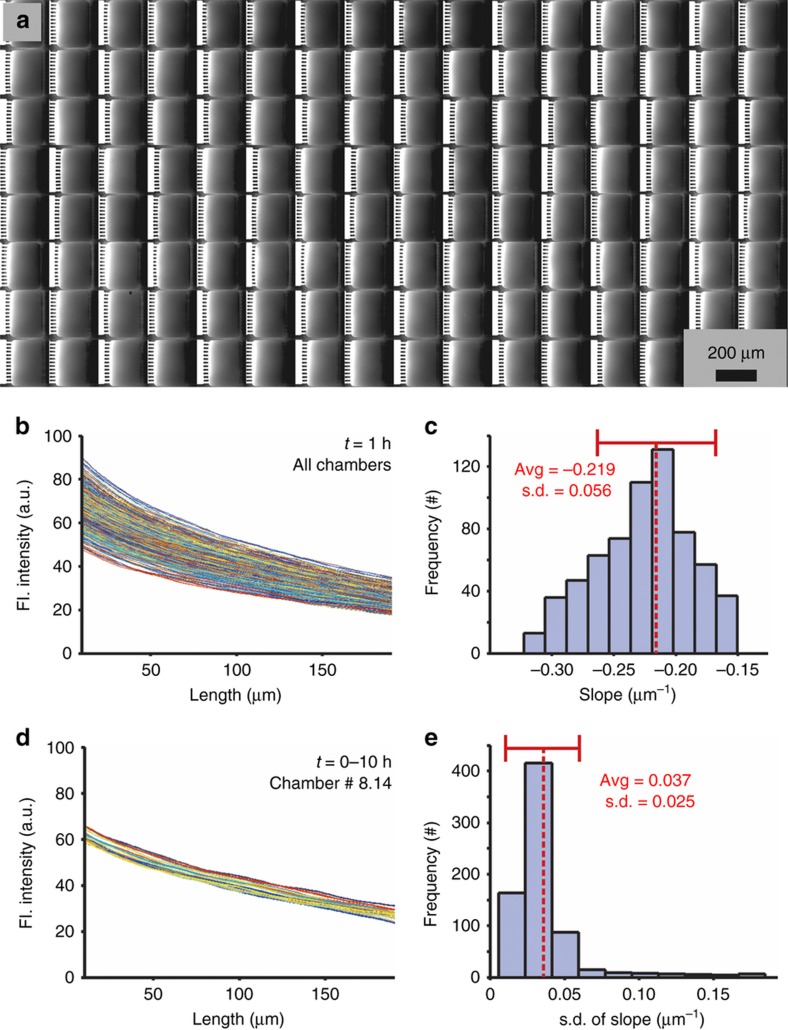

Figure 3.

Surface gradient characterization. (a) A montage of cropped fluorescent images from 8×16 contiguous chambers of the microjet array device (1/8th of the total area of the device), where a gradient is formed by opposing streams of 1 mM fluorescein and 45 mM Orange-G. The fluorescence intensity in each image is proportional to the concentration of fluorescein just above the surface33. For clarity, alternate images have been flipped to ensure that the source of fluorescein is always lined up on the left. (b) A plot of fluorescent intensity line-traces (averaged over 10 pixels and obtained through the middle of the chamber) from all the working chambers in the device (n=720) taken 1 h after the initiation of flow. (c) A histogram plot of the best linear-fit slope angles of the line-traces in (b). The red dotted line denotes the average slope (−0.219 μm−1) with a standard deviation of 0.056 μm−1. (d) A plot of the fluorescent intensity line-traces from a typical chamber taken every 30 min for 10 h. (e) A histogram plot of the standard deviations of the slope angles over time for all the 720 chambers plotted in (b). The red dotted line denotes the average standard deviation of the slope (0.037±0.025 μm−1).