Abstract

Purpose/objectives

The aim of the research was to develop a model that accurately represents an Aramany class II defect and its obturator prostheses fabricated with Cobalt Chromium alloy & Titanium alloy to compare the deflection and the stress distribution in the rehabilitated area.

Methods

Aramany class II defect and the obturator prostheses was generated geometrically utilizing ANSYS 14.5, both overlaid on each other to impressionist prostheses and the maxilla as one element. Meshing of models was carried out utilizing HYPERMESH software & materialistic properties were assigned. The 120 N load was constituted on the teeth in different directions.

Results

The stress distribution & deflection executed by ANSYS provided results that enabled the tracing of Von Mises stress and deflection field in the form of color veiled bands with standards in Mega Pascal (MPa).

Conclusion

The study shows that Von Mises stresses are higher for the frame work fabricated with cobalt chromium alloy compared to Titanium alloy. The framework made of titanium alloy showed more deflection than cobalt chromium alloy.

Clinical implications

3D FEA can be performed on a computer without putting any stress on the human body from technical materials, which is especially difficult for maxillectomy patients.

Keywords: Aramany Class II defect, Cobalt chromium alloy, Titanium alloy, Finite element analysis, Von Mises stresses

1. Introduction

There has been rise in the number of people that have ablative surgery for tumors of the maxilla leading to maxillectomy, patients experience utmost difficulty in phonetics, deglutition & mastication with adverse psychological effect. Prosthetic rehabilitation can acceptably reinstate the functions with enhanced quality of life (Beumer et al., 1979, Miyashita et al., 2012).

Extensive invasion of maxillary bone has an obliterated impact on the biomechanics of an obturator. Effect of leverage and weight of the prostheses aggravates the stresses on the supporting tissues during function. Henceforth the, evaluation of the configuration, extent of the invaded maxillary lesion and the preserved teeth are key to the success of the prostheses.

Aramany Class II defect is a solitary, unilateral defect swamping premaxilla. Arch is simile to a Kennedy class II condition, where bilateral or tripodal strategy are preferred. Surgeons must be intimated for the improved prosthetic rehabilitation in a class II situation by planned surgery and complete removal of metastasis. Hence, one of the most commonly seen acquired defects of the maxilla involves the resection of the dentition and the alveolar bone involving the tumor site (Bridgeman et al., 1997, Parr et al., 2005, Vero et al., 2015) explicitly Aramany class II defect.

Finite element assesses multifactorial field variables such as stress distribution, hydraulics of the field and deflective nature and simulates a real time situation at points which are connected by strings. It mimics a spider web, so that a minimal change in a local region is transmitted throughout the structure with a suitable gradation of consistency and precision (Kumar et al., 2013). It enables to re-experiment many times, it can be performed on a computer software without putting any stress on the patient’s body from technical materials, which is specifically difficult for patients who have undergone surgery for removal of tumour. The results derived can be displayed in visual simplicity.

It has been observed that enough evidence was lacking to determine the masticatory and swallowing functions in maxillectomy subjects (Vero et al., 2015). It is known that the masticatory ability of the patient is significantly reduced after the surgical resection of the maxilla or mandible. The location, shape and size of the defect has a large impact on the retention, stability of the final prosthesis and loss of the supporting, limiting structures likewise has an unfavorable effect on the prognosis of the prosthetic treatment rendered.

Cr-Co alloy has remained the designated metal for partial denture prostheses but the usage of commercially pure titanium and Ti alloys for dental applications has amplified progressively since report of its application in 1977. Titanium is the most bio-compatible metal used for restorations and is also less rigid than cobalt chromium alloy, whose hardness is of concern, as it is harder than the tooth enamel, which can cause in vivo wear (Parr et al., 2005). The flexibility of titanium alloys has increased its usage in removable prosthodontics compared to cobalt-chromium alloys (Bridgeman et al., 1997).

The understanding of the distribution of the stresses and the deflection of the obturator can be observed with the help of Finite Element Analysis which is a gold standard research tool in its class. Three-dimensional FE analysis can be utilized to verify displacement pattern and deformation area with repetition, without designating any stress on the human body from technical materials, which is especially difficult for patients who have undergone surgery for removal of tumor. The results derived can be displayed visually in a very simple manner, because of its improved simplicity and reproducibility. Finite element analysis has gained acceptance for stress analysis and deflection.

A three-dimensional Finite Element model with framework for an Aramany class II obturator was designed to evaluate the stress and deflection pattern in the frameworks proficient of Cr-Co alloy and Ti alloy.

2. Materials and method

The Study was categorized as: Geometrical representation of model, meshing of model, assigning material properties, application of boundary condition, application of different load, analysis of stress pattern, & analysis of deflection patterns.

2.1. Geometrical representation of model

2.1.1. Modelling of the dentate maxilla with the Aramany class II defect

The algorithm in this study is to generate finite element models from computerized tomography scan (CT scan) data of a dentulous maxilla in which reference is based on the study by Miyashita et al., 2012. Contouring of data profiles were transformed into the x, y and z axis points and read by Finite element program which connects these axis points forming a line geometry known as wire frame modeling. Inter connecting these lines of each section formed surface geometry also known as surface modeling. Joined adjacent profiles created three dimensional volumes which defined the final solid geometry of the defect. Through this process the CT scan data was converted into three-dimensional solid model of the Aramany’s class II defect.

2.1.2. Modelling of the obturator frame work:

For this study an obturator model was manually drawn and the removable partial denture frameworks were designed following standardized procedures having complete palate major connector, canine cingulum rest, first molar and second molar occlusal rests with embrasure clasp, 0.01-inch retentive arm undercuts, and canine I- Bar retainer (Parr et al., 2005) (see Fig. 1, Fig. 2).

Fig. 1.

3D FEM Obturator framework fabricated for Aramany class II defect with standardized method.

Fig. 2.

3D FEM model with Obturator framework superimposed showing I- Bar retainer.

2.2. Meshing of model

HYPERMESH was utilized in constructing the models. Utmost care was taken during meshing to concentrate elements in the region of greatest interest of stress distribution & deflection pattern. The completed geometric anatomical model was formed of total number of 40,201 nodes and 224,642 elements (see Fig. 3).

Fig. 3.

Completed 3D FEM model with Obturator prostheses fabricated on Aramany class II defect.

2.3. Assigning material properties

The corresponding elastic properties such as young’s modulus (E) and poisons ratio (µ) of the bone, dentition on the non-defect side, cobalt chromium alloy, titanium alloy and acrylic resin were determined by literature survey. The geometric model was impregnated with materialistic properties (Miyashita et al., 2012, Akay and Yalug, 2015) (see Table 1).

Table 1.

Assigned materialistic properties.

| Materials | Young’s modulus (E) | Poisson’s ratio (µ) |

|---|---|---|

| Cortical bone | 14.7 | 0.3 |

| Dentin | 13.7 | 0.31 |

| Palatal mucosa | 0.68 | 0.45 |

| Acrylic resin | 2.83 | 0.45 |

| Cobalt-chromium alloy | 149 | 0.35 |

| Titanium alloy | 110 | 0.33 |

*Model is assigned respective values from the studies done by Miyashita et al & Akay et al.

*Young’s modulus (E) measured in GigaPascal (GPa).

2.4. Application of boundary conditions

For the boundary condition of the model, a supporting system was setup at the distal aspect of all the three sides symmetrically.

2.5. Application of load

The magnitude and the direction of the loading forces were derived from the studies (Eto et al., 2002, Wedel et al., 1994). 120 N vertical load was transferred in the occluso-gingival path on the teeth region of the prosthesis and 120 N horizontal load was transferred on the bucco-lingual path on the teeth region of the prostheses.

2.6. Analysis of stress pattern

A 120 N vertical & horizontal emulating masticatory forces were applied to model (Wedel et al., 1994) (Eto et al., 2002). Scrutiny of the model was done with ANSYS Version 14.5 by means of Von Mises stress analysis. Stress values beyond the yield strength of material leads to rupture. Hence, they play an important role in interpreting the stresses concentrated within the metallic framework of the prostheses (Ranger et al., 1995).

2.7. Analysis of deflection pattern

Areas of deflection in the model was evaluated using the vector deflection analysis.

3. Results

3.1. Stresses with cobalt chromium and titanium alloy framework

It was observed that the highest amount of stress or the maximum stress of 6.00 MPa was seen in the framework fabricated with cobalt chromium alloy on application of vertical load of 120 N which is considerably more than the maximum stress of 2.237 MPa seen with the framework fabricated with the titanium alloy. The minimum stress observed was 0.002 MPa seen in the framework fabricated with titanium alloy (Graph 1) (see Fig. 4, Fig. 5, Fig. 6, Fig. 7).

Graph 1.

Overall comparison of von mises stress distribution in the framework.

Fig. 4.

Stress Distribution of Co-Cr framework on application on vertical load.

Fig. 5.

Stress Distribution of Co-Cr framework on application on horizontal load.

Fig. 6.

Stress Distribution of Titanium framework on application on vertical load. *Figures depicting various color coding in the framework area. *Inky blue expresses the least stress whereas red shows the maximum stress in the area.

Fig. 7.

Stress Distribution of Titanium framework on application on horizontal load. *Figures depicting various color coding in the framework area. *Inky blue expresses the least stress whereas red shows the maximum stress in the area.

It was observed that there had been differences in the stress at the natural teeth and the contra lateral side, the maximum stresses observed here was 0.524 MPa on application of incisal load with the cobalt chromium framework. The minimum stress observed was 0.008 MPa on application of horizontal load in the bucco palatal direction with a cobalt chromium framework.

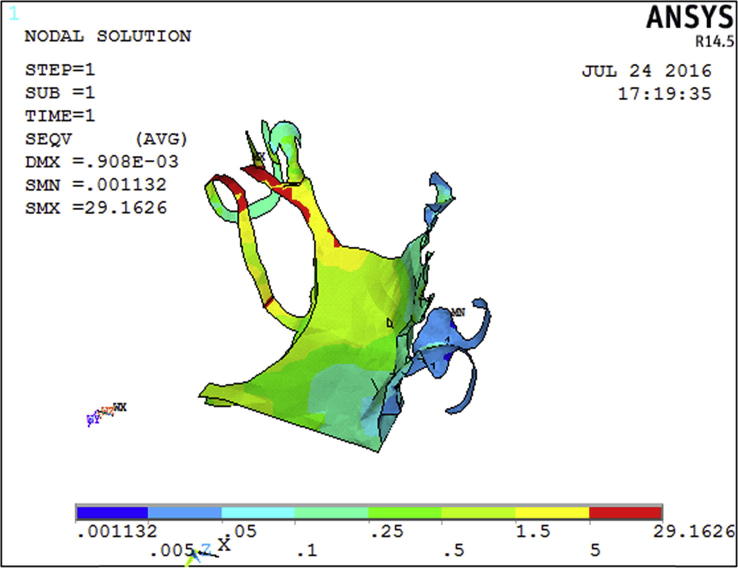

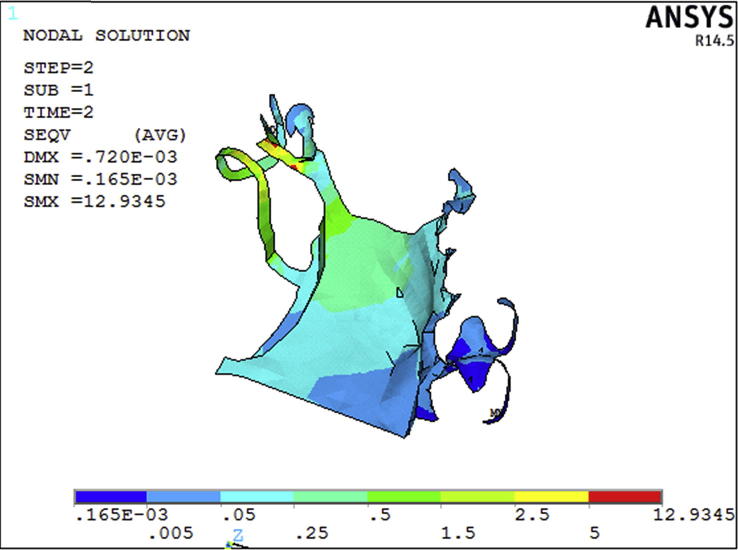

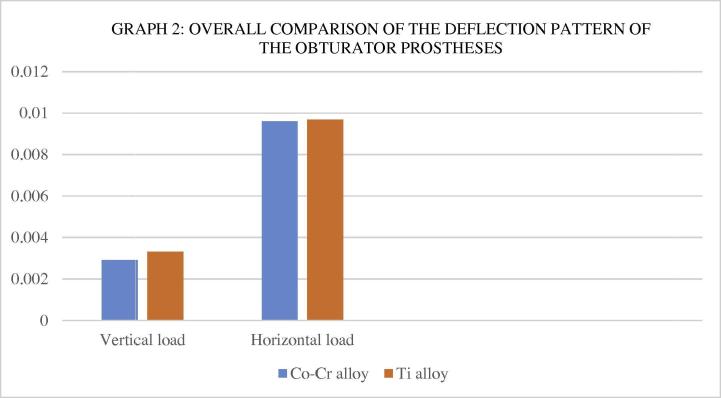

Deflection pattern between the obturator prosthesis fabricated with cobalt chromium alloy and titanium alloy (see Fig. 8, Fig. 9, Fig. 10, Fig. 11) (Graph 2).

Fig. 8.

Deflection pattern of Co-Cr framework under vertical loading.

Fig. 9.

Deflection pattern of Co-Cr framework under horizontal loading.

Fig. 10.

Deflection pattern of titanium framework under vertical loading. *Figures depicting various color coding on the prostheses area. *Red depicting the maximum stress on the teeth area.

Fig. 11.

Deflection pattern of titanium framework under horizontal loading. *Figures depicting various color coding on the prostheses area. *Red depicting the maximum stress on the teeth area.

Graph 2.

Overall comparison of the deflection pattern of the obturator prostheses.

It was observed that the highest maximum deflection value of 0.00968 mm was seen with Ti alloy framework when the load of 120 N was applied in the horizontal direction (bucco-palatal) and the minimum deflection value of 0.00291 mm was observed with the frame work fabricated with Cr-Co alloy.

4. Discussion

The degree of complexity in Finite element analysis is determined by the number, type of finite elements, physical and the mechanical behavior. Most of the analyses have treated the materials as having linear elastic properties, in which the structural deformation is unswervingly proportional to the engaged forces. Several dental studies utilizing finite element methodology have been considering biological tissues with isotropic properties. In the studies done by Miyashita et al., 2012, Gao et al., 2006, Zhao et al., 2008; the process of finite element analysis commenced with the creation of CAD model from the CT Scans of the selected biological structures, in addition a simplified tooth model without periodontal ligament was used to simplify the analysis of the result and the equivalent method has been followed in this current study. Finite element has been used in removable prosthodontic arena with very limited studies about the obturator prostheses. Clinically the location and size of the surgical resection and the patient’s oral status guides the prosthetic planning for obturator prostheses. Evaluating the stress distribution of the Aramany Class II prosthesis on the maxilla provides an understanding with biomechanics of the prosthesis which is central to prosthetic planning and preservation of the residual anatomical structures. Finite element analysis makes differentiating the material properties of the supporting structures and boundary with load conditions easier (Hase et al., 2014). Clinically the location and size of the surgical resection and the patient’s oral status guides the prosthetic planning for obturator prostheses. Evaluating the stress distribution of the Aramany Class II prosthesis on the maxilla provides an understanding with biomechanics of the prosthesis which is central to prosthetic planning and preservation of the residual anatomical structures.

Although the masticatory force varies for each individual and each food, a value previously established in a report that investigated occlusal force in partially edentulous patients with maxillary lesions where the magnitude and the direction of the loading forces were derived from the studies of Eto et al and Wedel et al.

4.1. Stress distribution

In this study 120 N load was applied in two different directions and stresses within the frame work and the intact natural teeth were individually analyzed. It was observed that the maximum stress was seen in the framework fabricated with the cobalt chromium alloy which was in accordance with study done by Miyashita et al and the supreme stress was seen when the incisor was subjected to the vertical load. In comparison the framework fabricated with titanium alloy showed lower stress values for the same load in the same direction. Overall, in this study the stress values obtained for the cobalt chromium alloy was considerably higher than that obtained from the titanium alloy framework irrespective of the focused area and the path of the determined load.

In addition, the stress on the natural dentition on the contra-lateral side was also seen, and it was observed that although the difference between the stress values obtained for both the frameworks was minimal, the stress value was slightly higher with cobalt chromium alloy. This can be attributed to the hardness of the cobalt chromium alloy which is more than that of the titanium alloy (Parr et al., 2005). It was pragmatic in this research that regardless of the path and area of the applied force the maximum stress concentration was seen in the central incisor of alloys studied. In both cases when vertical load was applied on the incisor and molar region the stress was focused on the cervical half of the root of the central incisors. On application of horizontal load, the stress was concentrated on the apical half of the root of the central incisors for both the frameworks.

4.2. Deflection pattern

In this study the deflection pattern is interpreted in millimeters. The difference between the deflection seen in the frameworks fabricated with cobalt chromium alloy and the titanium alloy was seen to be negligible, with the titanium alloy framework showing slightly higher values of deflection than the cobalt chromium framework. This result may be attributed to the greater flexibility exhibited by the titanium alloy when compared to the cobalt chromium alloy (Bridgeman et al., 1997). The deflection was perceived to be in the direction of the applied load.

4.3. Limitations of the study

Inspite of preciseness and accuracy for constructing & analyzing structures, the present study had few limitations. All the vital tissues in this study were isotropic instead of anisotropic. The loads that were applied were static load which is different from the dynamic load encountered during function. In this study lone type of acquired maxillary defect was considered (Aramany class II) and the stress within the framework and natural teeth were taken into consideration. The generation of the model imposed some simplification such as not including periodontal ligament. Hence, further research with improvements in the finite element models having the application of dynamic loading conditions can be done. Even though finite element analysis provides a sound theoretical basis of understanding the behavior of a structure in each environment, it should not be considered alone.

5. Conclusion

Maximum stresses were located within the cobalt chromium alloy framework irrespective of the concentrated area and determined force applied. Stresses were perceived to be maximum on the application of the horizontal load on the prostheses and the stress was concentrated on the proximal plate area. The deflection values which were interpreted in millimeters was seen to be almost similar in both the frameworks but the titanium alloy framework showed a higher overall deflection.

Conflict of interest

Authors hereby confirm that there is no conflict of interest.

Footnotes

Peer review under responsibility of King Saud University.

References

- Akay C., Yalug S. Biomechanical 3D FEA of obturator prostheses retained with zygomatic and dental implants in maxillary defects. Med. Sci. Monit. 2015;21:604–611. doi: 10.12659/MSM.892680. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Beumer J. St. Louis; Mosby: 1979. Maxillofacial Rehabilitation. [Google Scholar]

- Bridgeman J. Comparison of cobalt chromium & titanium removable partial denture clasps. JPD. 1997;78:187–193. doi: 10.1016/s0022-3913(97)70124-0. [DOI] [PubMed] [Google Scholar]

- Eto M., Wakabayashi N., Ohyama T. FEA of deflections in major connectors for maxillary RPD. IJP. 2002;15:433–438. [PubMed] [Google Scholar]

- Gao J., Xu W., Ding Z. 3D FE mesh generation of complex tooth model built on CT slices. Comput. Meth. Prog. Biomed. 2006;82:97–105. doi: 10.1016/j.cmpb.2006.02.008. [DOI] [PubMed] [Google Scholar]

- Hase H. 3D Finite Element Analysis of Aramany class IV obturator prosthesis with different clasp designs. Dent. Mater. 2014;33:383–388. doi: 10.4012/dmj.2014-015. [DOI] [PubMed] [Google Scholar]

- Kumar S. Deflection in mandibular major connector: A FEM Study. JIPS. 2013;13:560–570. doi: 10.1007/s13191-012-0191-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Miyashita E., Mattos B., Noritomi P., Navarro H. FEA of maxillary bone stress caused by Aramany class IV obturator. JPD. 2012;107:336–342. doi: 10.1016/S0022-3913(12)60086-9. [DOI] [PubMed] [Google Scholar]

- Parr G., Tharp G., Rahn A. Prosthodontic principles in the framework design of maxillary obturator prostheses. JPD. 2005;93:405–411. doi: 10.1016/j.prosdent.2005.02.017. [DOI] [PubMed] [Google Scholar]

- Ranger B. Bending overload and implant fracture. A retrospective clinical analysis. IJOMI. 1995;10:326–334. [PubMed] [Google Scholar]

- Vero N. Assessment of swallowing & masticatory performance in obturator wearers. A clinical study. JAP. 2015;7:8–14. doi: 10.4047/jap.2015.7.1.8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wedel A. Masticatory function in patients with congenital & acquired maxillofacial defects. JPD. 1994;72:303–308. doi: 10.1016/0022-3913(94)90344-1. [DOI] [PubMed] [Google Scholar]

- Zhao L., Herman J., Patel P. The structural implication of a unilateral facial skeletal cleft. A 3D FE model approach. Cleft Palate. Craniofac. J. 2008;45:121–130. doi: 10.1597/06-183.1. [DOI] [PubMed] [Google Scholar]