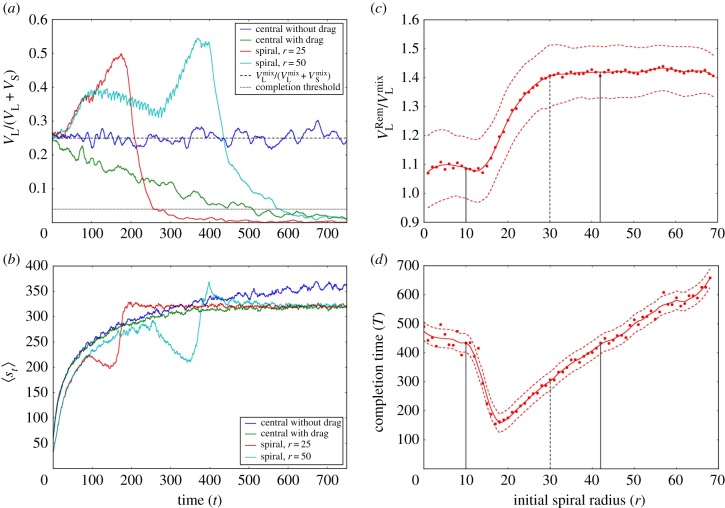

Figure 4.

Model results. (a) The fraction of the removal window volume occupied by large grains and (b) the average avalanche size, 〈st〉, over time for the spiral-digging and the null models with redistribution; solid lines: averages over 50 pit realizations; dashed line: expected volume fraction of large grains in the removal window based on large grains occupying 25% by volume in the original mixture; dotted line: 4% volume occupied by large grains in the removal window used to define a ‘completed pit’ (electronic supplementary material). (c) The ratio of the volume fraction of large grains ejected and large grains in the mixture, and (d) the time to pit completion against initial spiral radius, r, for spiral digging; red circles: averages over 50 pit realizations; solid red line: smoothed form of the relationship; dashed red lines: 95% CI envelope; dashed black line: final pit radius of 30 cells in the model (the average of 18 mm in the experimental pits, electronic supplementary material, table S1), at which the pit has a perfect small-grain lining; solid black lines: the spectrum of initial spiral radii, r, 10–42 (6–25 mm), where spiral digging offers substantial time savings over central digging. (Online version in colour.)