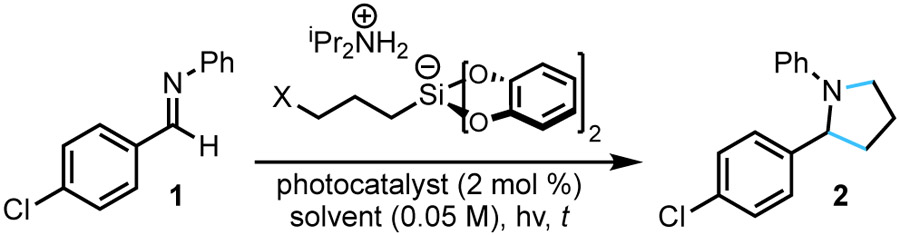

Table 1.

Optimization of the annulation process.a

| |||||

|---|---|---|---|---|---|

| entry a | X | photocat.b | solvent | time (h) | yield (%)c |

| 1 | Cl | [Ru] | DMF | 16 | 8 |

| 2 | Br | [Ru] | DMF | 16 | 20 |

| 3 | I | [Ru] | DMF | 16 | 10 |

| 4d | Br | [Ru] | DMF | 48 | 46 |

| 5 e | Br | [Ru] | DMSO | 16 | 46 |

| 6 e | Br | [Ir] | DMSO | 16 | 54 |

| 7e | Br | 4CzIPN | DMSO | 16 | 35 |

| 8 f | Br | [Ir] | DMSO | 16 | 60 |

| 9 f | Br | [Ir] | DMSO | 0.5 | 59 |

| 10f,g | Br | [Ir] | DMSO | 16 | – |

| 11f | Br | – | DMSO | 16 | 17h |

Conditions unless otherwise noted: silicate (5 equiv, 1.5 mmol), imine (1.0 equiv, 0.3 mmol), photocatalyst (2 mol %), DMSO (0.1 M), irradiating with 21 W CFL.

Photocatalyst: [Ru] = [Ru(bpy)3](PF6)2 and [Ir] = [Ir{dF(CF3)2ppy}2(bpy)]PF6.

Isolated yield after purification.

2 equiv of silicate used.

A 1:2 silicate/imine ratio used along with 4 W blue LEDs.

A 1:2 silicate/imine ratio used along with 30 W blue LEDs.

Reaction conducted in the dark.

NMR yield of crude reaction mixture.