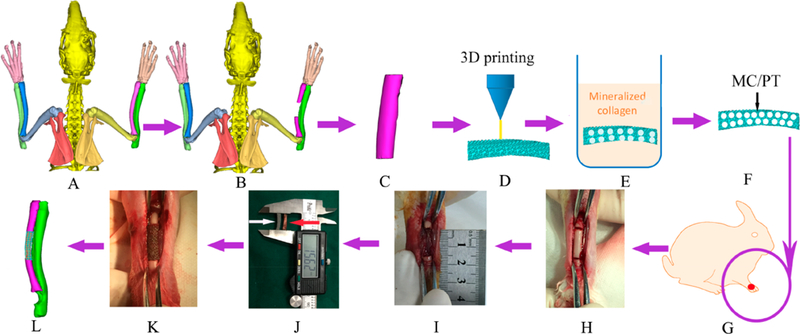

Figure 1.

Schematic of the overall idea. (A, B) A segmental bone defect (B) was formed in the middle of lateral radius of the healthy rabbit (A), as confirmed by micro-CT scanning. (C, D) On the basis of the micro-CT image of the bone defect (B) and by computer-aided design, a bone tissue model (C) fitting the profile of actual defect (B)was designed and reconstructed into a customized porous Ti6Al4V scaffold by 3D printing (D). (E-G) The porous 3D printed Ti6Al4V customized scaffold (termed PT) was filled with mineralized collagen (MC) by in situ mineralization to form a new scaffold (termed MC/PT) (E, F). PT and MC/PT were implanted into the middle of lateral radius (G). (H, I) To generate the bone defect, bone with about 1.5 cm in length along the longitudinal axis of radius was cut (H) and then taken out to form a defect (I). (J-L) To evaluate the scaffolds in repairing bone defect, the MC/PT scaffold (white arrow) was compared to the bone taken out of the animal to confirm that they have similar size and shape (J), then the MC/PT scaffold was implanted into the defect (K), and finally new bone and blood vessel were grown into the scaffold to achieve bone defect repair (L).