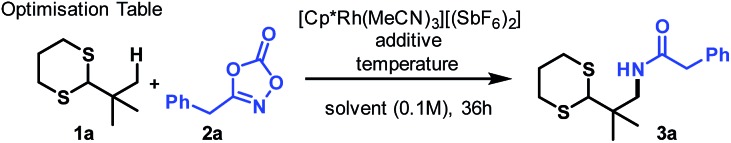

Table 1. Optimisation of reaction parameters.

| |||||

| Entry a | Solvent | Additive [mol%] | T [°C] | Cat. loading [mol %] | Yield b [%] |

| 1 | DCE | PhCO2 Na (40) | 80 | 10 | 16 |

| 2 | Toluene | PhCO2 Na (40) | 80 | 10 | 0 |

| 3 | Dioxane | PhCO2 Na (40) | 80 | 10 | Trace |

| 4 | CHCI3 | PhCO2 Na (40) | 80 | 10 | Trace |

| 5 | DCE | AdCO2 Na (40) | 80 | 10 | 23 |

| 6 | DCE | PivCO2 Na (40) | 80 | 10 | 18 |

| 7 | DCE | Amino acid (40) | 80 | 10 | Scheme 2 |

| 8 | DCE | Fmoc-Pro-ONa (40) | 80 | 10 | 55 |

| 9 | DCE | Fmoc-Pro-ONa (30) | 80 | 10 | 62 |

| 10 | DCE | Fmoc-Pro-ONa (20) | 80 | 10 | 57 |

| 11 | DCE | Fmoc-Pro-OK (30) | 80 | 10 | 0 |

| 12 | DCE | Fmoc-Pro-OLi (30) | 80 | 10 | 0 |

| 13 | DCE | Fmoc-Pro-OAg (30) | 80 | 10 | 0 |

| 14 | DCE | Fmoc-Pro-ONa (30) | 70 | 10 | 45 |

| 15 | DCE | Fmoc-Pro-ONa (30) | 90 | 10 | 47 |

| 16 | DCE | Fmoc-Pro-ONa (30) | 80 | 15 | 73(71) |

aReaction conditions: 1a (0.05 mmol), 2a (0.1 mmol), catalyst, additive, solvent (0.5 mL), temperature, 36 h.

bYield calculated by 1H NMR with methyl para-nitrobenzoate as internal standard; isolated yield of product in parentheses.