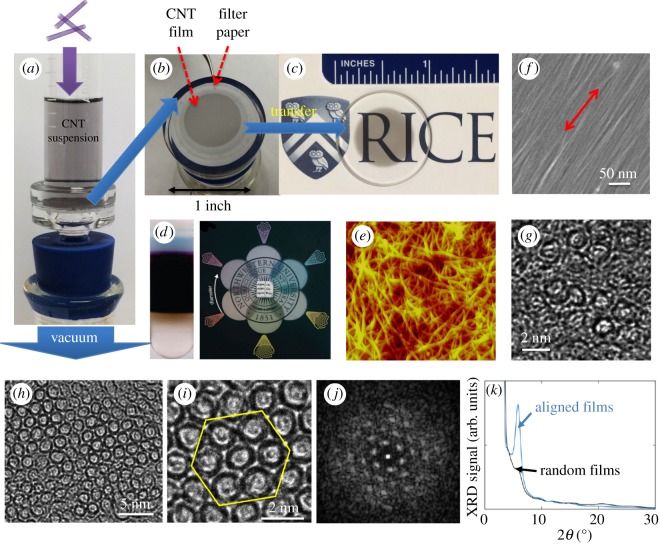

Figure 5.

Wafer-scale crystalline CNT films fabricated using controlled vacuum filtration. (a) A CNT suspension goes through a vacuum filtration system. (b) A wafer-scale, uniform CNT film is formed on the filter membrane. (c) Optical image of the produced film after being transferred onto a transparent substrate. (d) Separated mono-dispersed suspension using the density gradient ultracentrifugation method and fabricated semitransparent colourful films [68]. (e) A typical AFM image of random networks of CNTs fabricated using the conventional vacuum filtration technique [24]. (f) A high-resolution SEM image and (g) a cross-sectional TEM image of the film. Adapted from [66]. (h,i) Cross-sectional TEM images of a film produced by Falk and coworkers using the controlled vacuum filtration technique, showing crystalline CNTs with a high packing density approximately 3.8 × 105 CNTs μm−2. (j) A TEM diffraction image of a selected area in (i), showing a hexagonal lattice. (k) Grazing-incidence X-ray diffraction spectrum of a crystallized CNT film (blue curve), and a control film of randomly oriented CNTs (black curve). Adapted from [69].