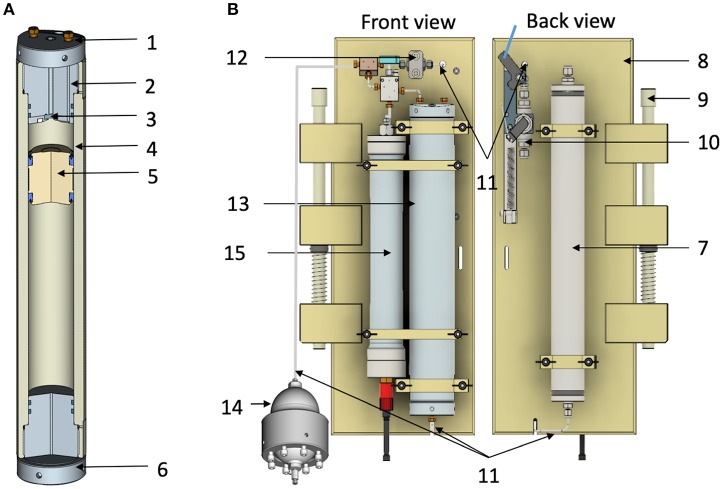

Figure 1.

(A) Cross section of the Titanium TA6V 500 mL High Pressure Bottle (HPBs). (B) Schematic drawing of the front and back views of the High-Pressure Sample Unit (HPSU). 1. Top end-cap devoted to oxygen measurement; 2. 1/8″ (3.2 mm O.D.) Inlet flowthrough; 3. Sapphire window; 4. Main core; 5. PEEK floating-piston with lip seal; 6. Bottom end-cap. In the part, above floating-piston seawater sample is in contact with sapphire window (see details in the text). The part below the floating-piston contains sterile milliQ water which serve as hydraulic brakes when passing through the thin catheter into the exhaust tank (7); 8. Polypropylene main frame; 9. Push rod for attachment to a rosette system. When the (10) inlet-valve is opened by magnetically activated lanyard release, the seawater enters the hydraulic circuit through a 1/8″ (3.2 mm O.D.) stainless-steel tube (11), via one check valve (12), to fill in the HPB (13), the pressure accumulator (14), and the aero-hydraulic pressure sensor (15).