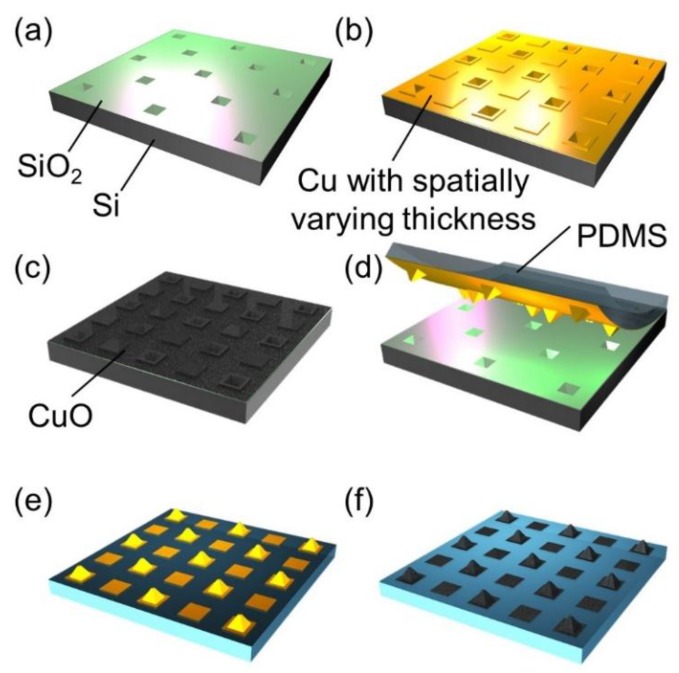

Figure 2.

A schematic illustration of the fabrication process of the hybrid surface with a 3D superhydrophilic pattern. (a) SiO2 is thermally grown on a prepared Si donor substrate where a pyramidal pit array is formerly made. (b) A Cu layer with spatially varying thickness is deposited on the Si donor substrate by two step electroplating. (c) Cu is oxidized by alkaline oxidation and a CuO-Cu composite layer is formed on the donor substrate. (d) A PDMS precursor is poured and cured on the donor substrate to mold a PDMS receiving substrate. Then the CuO-Cu composite layer is peeled off from the donor substrate and transferred onto the PDMS receiving substrate. (e) The Cu pattern is created after timed etching of the CuO-Cu layer on the receiving substrate. (f) The additional oxidation converts the Cu pattern to the CuO pattern.